Terminal Block Complete Guide: What It Is, Types, And Choosing the Right One

Author:admin Date: 2025-05-30 06:26 Views:941

Different methods can be used to connect two wires. Some people might decide to twist them together, but is it recommended? Sometimes, using the right tools for an electrical job can help with good performance. That is why terminal blocks are recommended for those who want to connect one or multiple wires.

What is a Terminal Block?

A terminal block is a type of modular electrical component vital for providing a safe and reliable way to connect or disconnect wires in a power system. There is no need for crimping or soldering when you use a terminal block.

There might be different types of terminal blocks in the market, but they all work in a similar way. You just need to get the right type for the application and you should be good in terms of connecting different wires together.

Key Parts of a Terminal Block

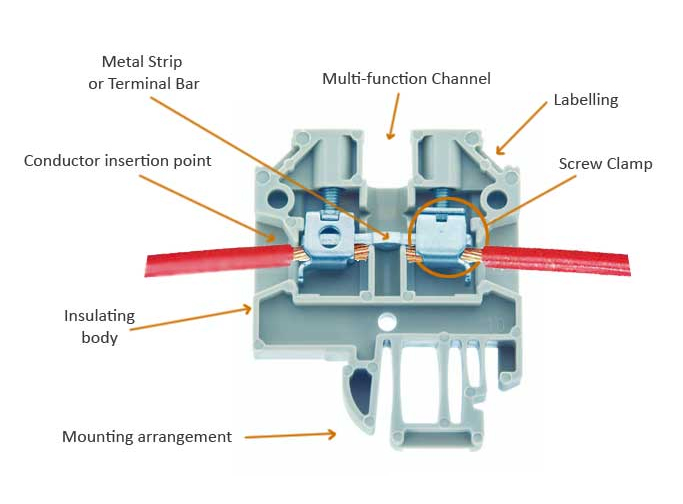

Single-level pass-through terminal block internal structure

The various parts of a Wago terminal block determine how well it does its job. The main components include:

- The body or housing holds the terminals and further provides mechanical support to the components, keeping them in place.

- The contacts are the metal parts that complete the circuit once connected to the wires.

- The clamps or screws are the mechanisms that secure the connected wires tightly to ensure a good electrical connection.

- Insulators are also part of the din rail mount terminal blockto prevent potential electrical leakage between the mounting surface and contacts.

- Identification tags are optional but can be key in identifying the connections, aiding in maintenance, and troubleshooting.

Terminal Block Electrical Specifications

Several electrical specifications of an electrical terminal block help you understand it better.

Voltage Rating

This is the maximum amount of voltage that the terminal block connector can handle before it is damaged. This is mostly influenced by the pitch or space between the poles and the strength of the housing material.

So, the voltage rating of a terminal block should be more than the maximum system voltage to prevent any damage to the terminal block strip.

Current Rating

Just as the voltage rating is essential, the current rating is also important. This can be described as the maximum nominal current the terminal block can handle per pole. We want the terminal block’s current rating to be at least 150% more than the anticipated maximum current. This helps with handling overcurrent situations.

Wire Range

This one specifies the wire sizes you can use with a terminal block. Different applications need different wire gauges. You have a range that can work in a certain terminal block. As such, it makes the electrical terminal block more versatile. Always choose a terminal block that can handle a wide range of wires based on the application.

Pole Count

The pole count of a screw terminal block determines the number of circuits it can handle. The number of poles varies greatly depending on the unit you get. Some can have up to 24 poles to support many circuits.

Types of Terminal Blocks

You can expect to come across different types of terminal blocks. They are categorized based on connection method, function, and mounting style.

Connection Method

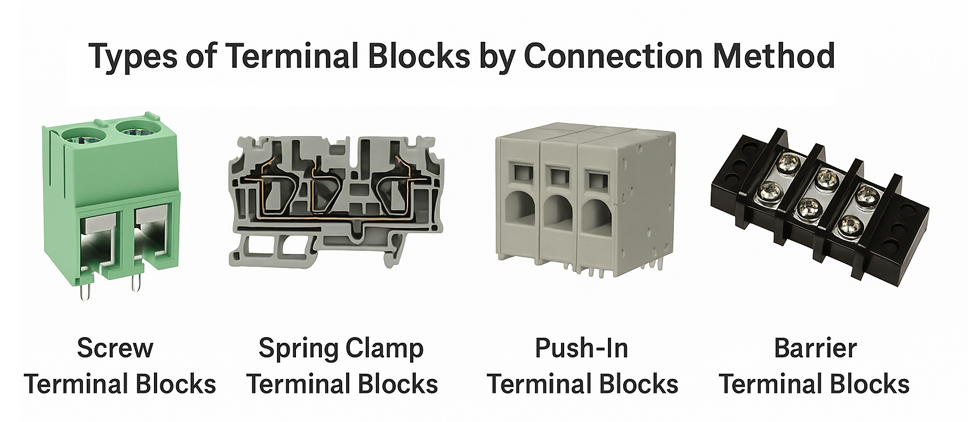

This refers to the way the wires are connected to a terminal block. The common types include:

- Screw terminal blocks where the wires are inserted into a metal clamp, and then a screw is tightened to hold the wire in place. These terminal blocks are good for strong and reliable connections. That is why they are common in industrial and commercial settings.

- Spring clamp terminal blocks have a spring-loaded mechanism that clamps down the wire to keep it from moving. They are best for vibration-resistant applications and require no tools to work with.

- The push-in terminal blocks automatically hold the wires once you push them into them. There are no screw issues whatsoever, and it is the fastest way to install the wires in a terminal block.

- Barrier terminal blocks come with metal barriers where a wire is inserted. The metal barriers serve multiple roles, including preventing shorts in the circuit. They are good in terms of safety and isolation. Expect to use them with audio setups, power equipment, and HVAC systems.

Function

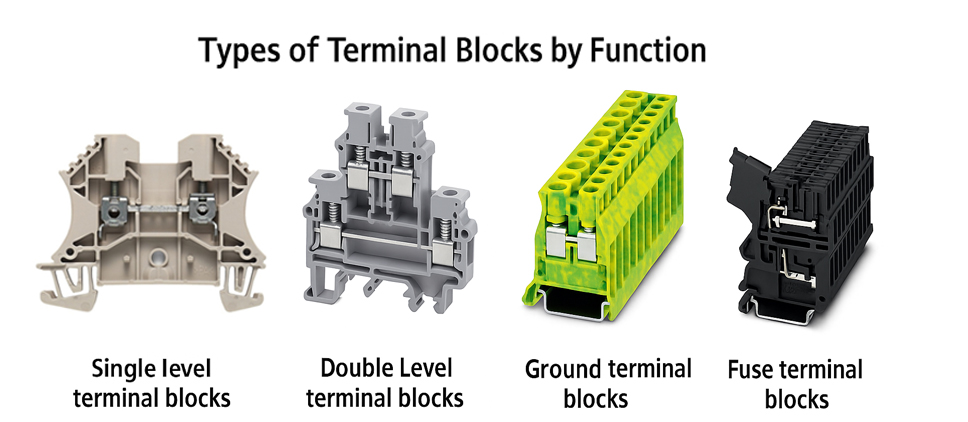

This is where you can categorize the terminal blocks based on their specific electrical application. Here is what you will get.

- Single-level terminal blocks come with one connection point for each terminal. This design is simple and efficient and works for most standard wiring needs.

- Dual-level or multi-level terminal blocks are the opposite of single-level. In this case, you can stack two or more connections in the same space. This design is focused more on saving space in panels or control cabinets. It is ideal when doing complex wiring.

- Ground terminal blocks are built to connect the wires to the electrical system’s ground. They often have a green or yellow color code. They are crucial for safety compliance and further system protection.

- Fuse terminal blocks feature a fuse holder. This is key to adding another layer of protection for the connected circuits. The fuse holder also makes it easy to replace the fuse without necessarily disconnecting the wires. This is common in power distribution and automation systems, where protection against overcurrent is crucial.

Mounting Style

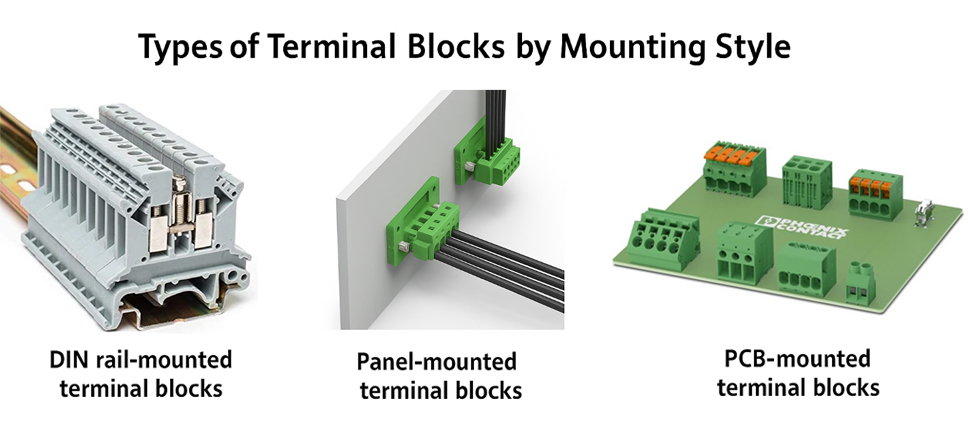

The terminal blocks can also be categorized based on the mounting style. Examples include:

- DIN rail-mounted terminal blocks that easily snap onto metal DIN rails. Because of this, they are easy to install, reorganize, or remove. This is a common mounting style for industrial applications.

- Panel-mounted terminal blocks are screwed or bolted onto an enclosure or panel. The panel is key for providing a strong mechanical stability but might need tools to install the terminal blocks. We recommend them for applications with high vibration.

- PCB-mounted terminal blocks are mounted directly onto a PCB through soldering. They are usually smaller and best suited for low-voltage electronics. They are common in consumer electronics, communication devices, and instrumentation.

Applications of Terminal Blocks

The wire terminal blocks come with many applications. Examples of such applications include:

- Industrial automation is a big user of terminal blocks. This is where sensors, control systems, and actuators are connected through terminal blocks.

- The other popular use of terminal blocks is power distribution. This is generally a safe and reliable way of connecting power cables.

- The terminal blocks are also common in control panels for organizing and managing wire connections.

- HVAC systems also use such components together with actuators and thermostats to ensure a proper electrical connection.

- Motor control can also be achieved by securely holding the motor leads with terminal blocks. This prevents overheating compared to simply twisting the cables together.

Depending on your needs, you may find a Weidmuller terminal block more useful. Always review the types of electrical wire terminal blocks to identify the correct ones.

How to Choose the Best Terminal Block

Before you can buy that PCB terminal block, there are a few things to keep in mind to ensure you get the right one. Here is what to consider.

Electrical Specifications

We have already mentioned about this. The current and voltage ratings of the wire terminal block are important for you to consider. Only choose a model that can handle the power going through the wires to avoid potential electrical hazards.

Look at the terminal block’s data sheet to see if it can handle your application’s power needs.

Mounting Options

Yes, you will encounter different types of mounting options for terminal blocks. The common options include panel mount, PCB mount, and rail mount. Each one has a place in electrical systems. It comes down to what you need at the time. Pick one you can comfortably mount and connect circuits through it.

Terminal Block Features

Of course, you need something designed for performance. For example, screw terminal blocks offer more flexibility so that you can work with various wire sizes as long as they need manual tightening.

The push-in terminal blocks make inserting and removing wires easy with minimal force.

Look at the other clamping mechanism the battery terminal block offers. Whichever you choose, make sure it helps you achieve secure wire connections.

Maintenance and Accessibility

If you have to change a wire, you need a terminal block with a better accessibility design. This includes the wire entry orientation position. Some positions make it easier for you to replace the wiring where necessary.

Environmental Considerations

These are key in determining if you will get terminal blocks that can work well in your operating temperature. If the terminal block can withstand the operating temperature, the better. This information will be included in the datasheet to help you pick better.

Mistakes to Avoid with Terminal Blocks

Sometimes, the terminal block might not work as expected because you have made errors. Below are some mistakes to avoid if you want the Allen Bradley terminal blocks to work correctly.

- Underspecifying the current and voltage ratings. This means the current going through the terminal block will be higher, leading to overheating and sometimes fire hazards. The solution is to have terminal blocks with a safety margin of 150% for the current and 20%, depending on the application’s requirements.

- Ignoring wire compatibility can lead to issues. You do not want to end up with too large or small wires for the terminal block. It will simply lead to poor electrical connections or fitting.

- Do not neglect environmental factors such as high temperatures, vibrations, humidity, etc. This is because they can potentially lead to premature degradation or failure of the Wago terminal blocks.

Where to get Quality Terminal Blocks

The best way to get a 12V terminal block or fuse terminal block, is by choosing from top brands. Examples of such brands include TE Connectivity, Phoenix Contact, WAGO, ABB, Weidmuller, and more. Read several reviews about the brand to identify if it is suitable for quality terminal blocks.

Check out your local electronics shop to see if it has the right terminal block you need. Also, online shops can be a good place to get quality PCB screw terminal blocks so long as you already know the top brands to buy.

Conclusion

We have gone through about what is a terminal block, the types, applications, how to buy, and other information. Right now, you can get a din rail-mounted terminal block and wire it correctly because you understand its use. We expect people to have now better electrical connections that do not overheat or lead to electrical fires as they can use the right tools. Do not forget to buy from top brands to get the right performance for a din rail screw terminal block or any other type.

Please send RFQ , we will respond immediately.

Frequently Asked Questions

How can you find the right terminal block for an application?

Always consider factors such as the current and voltage rating, the connection method, mounting style, environmental conditions, and wire size compatibility.

Is there a difference between DIN rail and panel-mounted terminal blocks?

DIN rail-mounted terminal blocks easily clip onto the standard metal DIN rails. This makes them easy to install without tools. As for the panel-mounted terminal blocks, you have to attach them to a panel with screws. This leaves you with a strong mechanical stability key for rugged applications.

Can terminal blocks work for both high-current and voltage applications?

Yes, it is possible to find terminal blocks built to handle high current and high voltage. This is done using heavy-duty materials and better insulation.