Insulated Gate Bipolar Transistors’ Role in Electric Vehicles

Author:admin Date: 2025-10-18 02:16 Views:159

- Introduction

- How Does an Insulated-Gate Bipolar Transistor Work

- Benefits of Using IGBTs in Electric Vehicles

- Role of IGBTs in EV Powertrain

- Challenges and Limitations of IGBTs in EVs

- How To Test an Insulated Gate Bipolar Transistor

- Conclusion

- Video: What is IGBT? How it Works? Working of Insulated Gate Bipolar Transistor with 3D Animation

Introduction

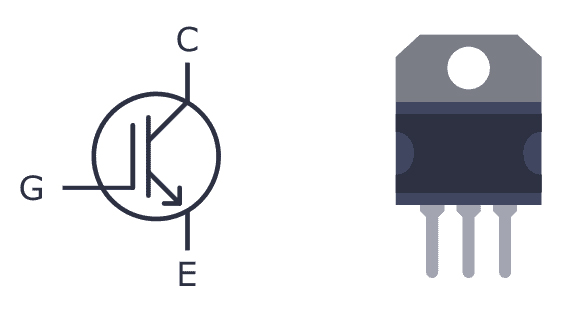

An Insulated Gate Bipolar Transistor (IGBT) is a power electronic device used as a switch to control a large amount of electricity. This transistor combines the high input impedance and fast switching capability of a MOSFET and the high current-handling capability of a BJT.

The IGBT features three main terminals: the gate, emitter, and collector. Thanks to its performance, the transistor is useful in high-power applications such as electric vehicles, industrial controls, and motor drives.

How Does an Insulated-Gate Bipolar Transistor Work

We have already looked at the definition of the insulated-gate bipolar transistor. We now want to focus on how it works.

The three terminals include:

- Gate, which is an insulated metal electrode controlled by a voltage

- A collector, which is a terminal where the holes are injected into the drift region

- An emitter is a terminal that provides electrons to the channel and also connects to the N+ region.

When there is no or a small negative voltage applied to the gate, there are no conductive channels formed under the insulated gate. At this point, the insulated gate bipolar transistors work as an open switch. It is in this mode that the current is blocked between the emitter and collector.

A sufficiently enough positive voltage (above threshold voltage) is needed to create an electric field across the insulating oxide layer.

The generated field induces an inversion layer of electrons in the P-type region. You now end up with a conductive N-channel between the N-drift region and the emitter.

The same thing happens when a positive voltage is applied to the collector. It causes the P+ substrate to inject holes into the N-drift region.

During the conduction state, a combination of the electron channel and the injected holes creates a high number of charge carriers in the drift region. The result is increased conductivity.

At this point, a large current can flow from the collector, through the drift region and channel, and finally to the emitter. That is how it can be used for running electric vehicles.

When you remove or reduce the gate voltage below the threshold, the conductive channel collapses, turning off the IGBT. At this point, the IGBT returns to its off state, blocking the current from flowing between the collector and emitter.

Benefits of Using IGBTs in Electric Vehicles

The insulated gate bipolar transistor basics show how good it can be for electric vehicles. However, how? Here are some of the key benefits of using IGBTs for electric vehicles.

- IGBTs can handle high power demands, which is what you get with the EV motors. It is capable of handling high voltages and large currents required for vehicle propulsion.

- They come with a hybrid design, which is important for minimizing power lost as heat. This leads to greater overall efficiency. Such improved energy conservation is vital for extending the EV’s driving range.

- Fast switching speeds of IGBTs enable precise regulation of electrical power. This is key for smooth acceleration or deceleration. There will also be efficient energy conversion depending on the needs of EV motor drives.

- IGBT modules come with a compact design. This is why they can be space-efficient, allowing for lighter components to be added to the EV platform and making it less heavy. Most car manufacturers would want lighter components, and this is such a good addition.

- Integrated protection is also possible with most modern IGBT modules. These built-in protection features include thermal shutdown and overcurrent protection. This enhances the reliability and safety of the system.

- You gain simple control with the insulated-gate bipolar transistor module. Its structure requires very little energy to enable the switching aspect. Therefore, it simplifies the design and reduces the cost of control units required to manage power.

Role of IGBTs in EV Powertrain

IGBTs are particularly useful for traction applications. This is because they can convert the high-voltage direct current from the EV’s battery into the alternating current needed for powering the electric motor.

Since the IGBT can deliver rapid switching, the power on and off leads to precise control of the electric motor’s torque and speed. The result is a smooth, silent, and responsive driving experience.

IGBTs are also vital in charging the EV. This is because they aid in converting the AC from the household power outlet into direct current to charge the EV’s battery.

You may also come across fast charging stations with IGBTs. This is where they are used for managing the rapid flow of electricity from the grid into the EV’s battery system.

Challenges and Limitations of IGBTs in EVs

MOSFETs generally have a higher switching speed than IGBTs. This means there can be higher switching losses or reduced efficiency. However, tests show the IGBT speeds are still good enough for them to be useful in EVs.

There might be high switching losses because of the tail current effect during the turn-off period. This issue may lead to increased power loss and the generation of extra heat, especially at high frequencies.

Thermal management might also be an issue as IGBTs produce waste heat. This needs to be managed efficiently, or it may lead to reduced lifespan or a damaged device.

Sensitivity to humidity is another reason to keep the IGBTs well insulated. This is because the moisture affects the operational conditions and lifespan of IGBT modules.

The integrated gate bipolar transistors also have high manufacturing costs compared to other similar transistor types.

How To Test an Insulated Gate Bipolar Transistor

Testing the IGBTs helps determine if they are in good working condition or not. You will need a voltage supply and a digital multimeter for checking the resistance.

Here is how to test the IGBT:

- Discharge and power off the IGBT by disconnecting it from any power source.

- Virtual inspection is a good way to determine whether there is physical damage, such as burns, cracks, and other signs of failure.

- Test the IGBT with the multimeter in diode mode. Place the positive probe on the collector and the negative probe on the emitter.

- A good IGBT will have a diode-like forward voltage drop and less resistance. When you reverse the probes, you should get an open-circuit reading, as there is no reverse conduction. A shorted IGBT will show continuity when it is supposed to show an open circuit.

We recommend consulting the IGBT datasheet for specific configurations and excited voltage or resistance values. If the tested figures differ from the values, then the IGBT has a problem.

Conclusion

The insulated gate bipolar transistor is vital in EVs through various applications. This includes acting as a high-power switch in the motor inverter, converting DC battery power to AC for the motor’s traction. Proper maintenance is crucial to ensure optimal performance. Additionally, test them regularly to ensure they continue to function correctly.

Video: What is IGBT? How it Works? Working of Insulated Gate Bipolar Transistor with 3D Animation

Please send RFQ , we will respond immediately.

Frequently Asked Questions

Why are IGBTs more preferred over MOSFETs in electric vehicles?

Although MOSFETs are faster, IGBTs are preferred because they can handle higher voltages and currents more efficiently. Keep in mind that EVs may operate at several hundred volts, and IGBTs can effectively manage this power while also reducing low conduction losses.

Where do you find IGBTs in an electric vehicle?

IGBTs can be found in various components such as motor inverters, onboard chargers, DC-DC converters, and motor control units.

Are there challenges to using IGBTs in EVs?

The main challenge is heat management. This is because they generate heat during high-power operations, thus requiring advanced cooling systems. They may also have a lower switching speed compared to newer technologies such as Silicon Carbide (SiC), which can impact the efficiency at high frequencies.