Laser Diodes: Operation, Uses, and Buying Tips

Author:admin Date: 2025-12-03 10:14 Views:97

Introduction

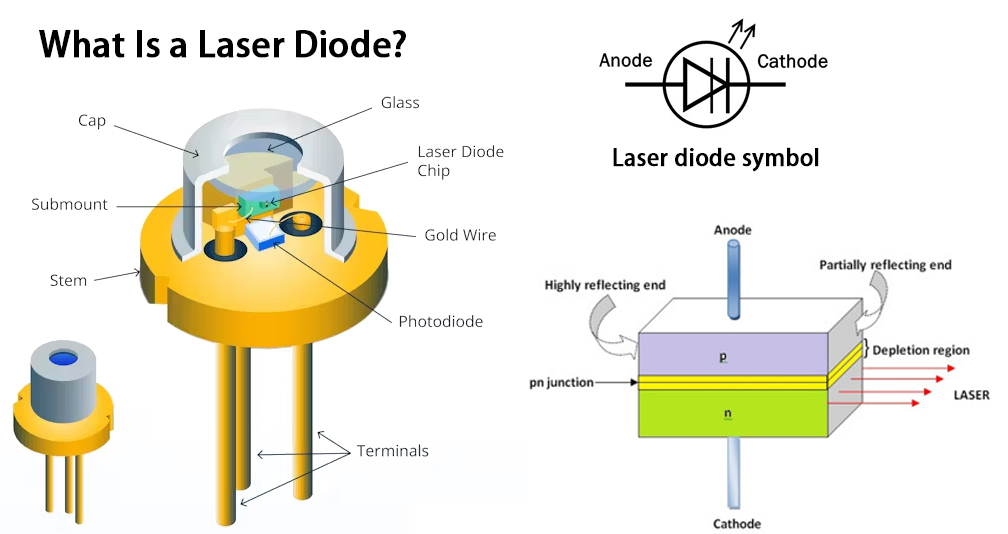

A laser diode is a semiconductor device used for producing coherent, monochromatic light through a stimulated emission process. It is basically an electrically pumped p-n junction diode designed to emit laser light rather than incoherent light.

Internal Structure of a Laser Diode

The internal structure of laser diodes includes a sophisticated multilayer double heterostructure that incorporates quantum walls. This is what confines both electric charge carriers and photons to maximize laser efficiency.

The primary internal components of laser diodes include:

Active Layer or Active Region

This is the laser diode core. It is a very thin, undoped layer of a direct-bandgap semiconductor.

When the region is forward-biased, electrons from the n-side and holes from the p-side are injected into this region. They are then recombined to produce photons through stimulated emission. The material’s bandgap determines the wavelength of the emitted light.

Cladding Layers (P-type and N-Type)

The active layer is sandwiched between the n-doped and p-doped cladding layers. They are made of a wider bandgap material. These layers are used to perform a dual function, including carrier and optical confinement.

For carrier confinement, the bandgap difference creates potential barriers that trap the electrons and holes in the narrow active region. This increases their density.

In optical confinement, the cladding layers have a lower refractive index than the active layer. This creates an optical waveguide that limits photons to the active region through total internal reflection. This ensures they pass back and forth through the gain medium for amplification.

Substrate

The entire structure is grown epitaxially on a thicker semiconductor substrate. This provides mechanical support and a base for electrical contact.

Optical Resonator

Optical feedback is required for laser action to occur. In edge-emitting laser diodes, the crystal is cleaved at two opposite ends along natural crystal planes to form highly flat, parallel facets.

Once facet is often coated to be highly reflective, while the other is left partially reflective. This allows a portion of the amplified light to escape as the laser beam.

Metal Contacts

Metal layers are deposited on the top and bottom of the device so as to provide electrical connections for the external power source.

Monitor Photodiode

This is an optional layer, but many packaged laser diodes include a separate, integrated photodiode to monitor the light output from the rear facet of the laser chip. Such feedback is important for control circuits for maintaining a constant, stable output power and further preventing damage.

How a Laser Diode Works

A laser diode works by using electrical current injection to create a condition called population inversion in a semiconductor material. The light is then amplified through stimulated emission within an optical cavity.

Here is the process in detail:

- Electrical Pumping and Carrier Injection

An external power source applies a forward bias voltage across the p-n junction of the diode. This causes the electrons from the n-type semiconductor and holes from the p-type semiconductor to be injected into the active layer in the middle of the junction.

- Spontaneous Emission

In the active layer, the holes and electrons naturally recombine. As the electron drops from a higher energy level to a lower energy level to fill a hole, it releases energy in the form of photons.

Initially, this process occurs randomly, leading to spontaneous photon emissions in various directions and phases, similar to how an LED works below its operational threshold.

- Population Inversion

As the injection current increases, more holes and electrons flood the active region. A non-equilibrium condition is reached, meaning the number of electrons in the conduction band exceeds the number of holes in the valence band. This state, known as population inversion, is vital for laser action.

- Stimulated Emission and Light Amplification

In this case, a spontaneously emitted photon travels through the active region, it will encounter an excited electron. This incoming photon will stimulate the electron to recombine with a hole and emit a second photon.

The second photon is identical to the first. It will have the same wavelength, phase, direction, and polarization. This cloning effect is what amplifies the light.

- Optical Feedback and Lasing Threshold

The active region is situated in the optical cavity, which is typically formed by cleaving the ends of the semiconductor crystal. This creates two parallel and reflective facets.

The photons bounce back and forth between the mirrors, thus passing through the active medium to stimulate more emissions. This creates an avalanche of identical photons.

When the amplification gain within the cavity surpasses the losses, then the diode reaches its threshold current and begins to lase or produce intense coherent light.

- Laser Light Output

One of the facets is designed to be partially reflective. This allows a portion of the highly amplified, coherent light to escape as a concentrated, narrow laser beam.

Key Operating Characteristics of Laser Diodes

The laser diodes have operating characteristics that describe both the properties of the emitted light and the electrical parameters of their operation.

Wavelength

The primary frequency or color of the emitted light is measured in nanometers. Such is determined by the semiconductor material’s bandgap energy. Changing the operating temperature or current can shift the wavelength.

Output Power

Laser beam intensity is measured in milliwatts or watts. The output power increases sharply once the operating current exceeds the threshold current.

Coherence

Laser diodes produce highly coherent light. This means emitted photons have the same frequency and phase. Such allows the beam to be focused to a very small, diffraction-limited spot.

Monochromaticity

The light is highly monochromatic, meaning it consists of a very narrow range of wavelengths.

Spectral Width

This is the actual wavelength range present in the output. While monochromatic, most basic laser diodes exhibit multiple longitudinal modes having a narrow spectral width.

Threshold Current

This is the minimum forward current required for the device to transition from an LED-like state to laser action.

Types of Laser Diodes

Laser diodes are largely categorized based on their light confinement and feedback mechanisms. Here are the main types of laser diodes.

Fabry-Perot Laser Diodes

The FP laser diode is the most popular on the market. It uses the natural reflectivity of the cleaved semiconductor facets to form an optical resonator.

It is typically multi-mode as it emits several wavelengths simultaneously, which results in a broader spectral width. You can expect them to be cost-effective due to their simple design.

The common applications for this type of diode include fiber optic communications, CD/DVD players, and low-cost general-purpose uses.

Distributed Feedback Laser Diodes

These lasers incorporate a periodic grating structure within the active region of the semiconductor. The internal grating acts as a wavelength-selective filter, providing feedback to only a single longitudinal mode. Such results in a highly stable single-frequency output having a very narrow linewidth.

Distributed Braff Reflector Laser Diodes

These are similar to the DFB lasers above, but the grating structures are placed in passive regions, which are outside the active section.

This configuration is intended to allow higher output power than the DFBs. This is because the grating section is not part of the gain medium. The multi-electrode DBRs also offer a wider, though potentially mode-hopping, tuning range.

Vertical-Cavity Surface-Emitting Lasers

Unlike edge-emitting lasers, which emit light along the wafer surface, these lasers emit light vertically from the chip surface.

These lasers feature circular beam profiles, low threshold currents, and can be manufactured and tested on a single wafer in 2D arrays. This leads to low-cost mass production.

Quantum Cascade Laser Diodes

Such laser diodes operate differently. They are unipolar devices that rely on intersubband transitions in the engineered quantum wells rather than using the traditional electron-hole recombination across the bandgap.

These laser diodes operate in the mid-infrared to terahertz spectral range. This is a hard region to access when using the conventional diode lasers.

High-Power Laser Diodes

This type of laser diode is designed to maximize optical output, often using diode bar/stack or broad area architectures.

Such diodes sacrifice beam quality and single-mode operation for sheer power. They require an efficient thermal management system.

Laser Diode Applications

Laser diodes are used across a vast spectrum of applications. This is because they are compact, highly efficient, and offer precise control.

Expect to come across various applications of laser diodes, including:

- Telecommunications and data communications

- Consumer electronics such as optical storage, barcode scanners, printers, and pointers

- Industrial and manufacturing, including material processing, 3D printing, and metrology

- Medical and healthcare fields, including surgical procedures, aesthetic treatment, and spectroscopy

Laser Diode Drivers & Electrical Requirements

Driving a laser diode is important for having a safe operation, stability, and maximum lifespan.

Constant Current Drivers

These are the most common drivers and a highly recommended method for driving laser diodes. They provide you with a stable, user-adjustable current regardless of the changes in the load resistance or input voltage.

Constant Power Drivers

These drivers use feedback from a monitor photodiode integrated into the laser diode package. The driver dynamically adjusts the injection current so as to maintain a consistent optimal power output. They compensate for changes caused by temperature fluctuations or diode aging.

Protection Circuits

Laser diodes are extremely fragile components, so protection is vital. A simple static shock can instantly destroy the diode junction. Proper handling of the diodes and using the ESD suppression devices at the input is important.

Power supply turn-on/off spikes can exceed the maximum current rating. Soft-start circuits, which gradually ramp up current, are a common safety feature in high-quality drivers.

Applying current in reverse bias can permanently damage the diode. This is why protection diodes are placed in parallel to shunt harmful reverse voltage away from the laser diode.

Temperature Control

Temperature affects how a laser diode performs. An increase in temperature reduces the efficiency, raises the threshold current, shortens the lifespan, and also shifts the output wavelength.

Here is how you can handle thermal management in laser diodes:

- Heat sinks are the simplest form of cooling. Here, the heat sinks are used to dissipate the waste heat from the laser diode package to the ambient environment.

- Thermoelectric coolers use the Peltier effect to actively pump heat away from the laser diode chip actively. They are highly effective for precise temperature stabilization.

Buying Guide for Laser Diodes

Choosing the right laser diode requires careful consideration of the specific technical requirements for your specific application. Here is how you can choose the right laser diodes.

Wavelength

The specific wavelength is fundamental to how the laser diode interacts with materials or detectors. Red lasers are used for barcode scanning, while infrared lasers are used for fiber optics and medical devices. The wavelength determines the application.

Output Power

The power level is measured in milliwatts or watts. It must be sufficient for the application. High power in kilowatt levels is needed for industrial cutting, while very low-power diodes are used for sensing or alignment. It is best practice to choose a diode with a higher power capacity than what you need.

Beam Quality and Divergence

The quality is expressed by the M² factor, where values closer to 1 indicate a higher-quality, more focusable beam. Laser diodes naturally produce divergent, often elliptical beams; consider whether your application requires external optics to shape the beams.

Operating Mode

Determine whether you need continuous-wave operation for a steady beam or pulsed mode for quick bursts of light.

Package Type and Integration

Consider the physical packaging, such as the standard Transistor Outline package, and whether it has features such as a monitor photodiode for power control or a thermoelectric cooler for temperature management.

Reputable Brands and Vendors

Make sure you also buy from reputable vendors or brands to get high-quality products. Ask about their quality control processes, track record, and certifications.

A good supplier will provide you with comprehensive documentation, including detailed data sheets, strong technical support, and application notes.

Conclusion

The laser diode stands out as an important and transformative invention in modern physics and engineering. Right now, it is a compact, highly efficient, and durable light source that powers the global digital infrastructure and countless everyday devices. As technology advances, expect new variants of laser diodes to push the boundaries of applications, which makes the laser diodes indispensable.

Please send RFQ , we will respond immediately.

Frequently Asked Questions

Is there a difference between LED and laser diodes?

Yes. Laser diodes produce coherent, focused, directional light while LEDs produce incoherent, wide-angle light. This is why laser diodes are used for precision tasks while LEDs are for general illumination.

How long do laser diodes last?

The high-quality diodes can last up to 50,000 hours. This depends on the operating current, usage conditions, and temperature. Proper heat management can help extend the lifespan.

Why do laser diodes require a constant-current driver?

Laser diodes are highly sensitive to current fluctuations. A constant-current driver ensures stable output, protects the diodes from thermal runaway, and prevents current spikes.