Construction and Operation of Thyratrons: A Detailed Beginner Guide

Author:admin Date: 2025-12-16 08:32 Views:137

Introduction

A thyratron is a gas-filled tube that is used as a high-current rectifier and switch. It is considered an evolution of the vacuum triode that is filled with a low-pressure vapor or gas. The gas significantly alters its operating characteristics.

As solid-state electronics such as MOSFETs and IGBTs have replaced vacuum tubes, gas-filled tubes, such as thyratrons, still maintain a niche in high-power applications, as they are designed to handle high voltages and currents.

Construction and Working Principle of Thyratron

Understanding how thyratrons work can help in choosing the right application for them. Let us start with its internal structure.

Internal Structure

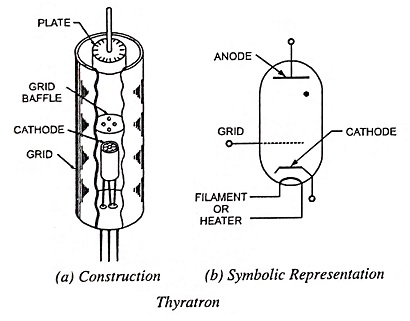

The internal structure of a thyratron is similar to a basic vacuum tube; however, it has specific design features for managing high power, and it also has gas.

Anode, Cathode, and Control grids

The cathode is a directly or indirectly heated filament used for producing a large flow of electrons.

The control grids are positioned between the cathode and the anode. The grid structure determines when the tube fires or turns on by controlling the electric field in the main discharge path.

The anode is the positive terminal that collects the high-current electron/ion plasma. The anode is also robustly designed to dissipate heat.

Gas Types

As earlier explained, thyratrons are filled with a low-pressure gas or vapor.

Hydrogen/deuterium is preferred for modern high-power, fast-switching applications. This is because of their rapid deionization times. As a result, you end up with higher pulse repetition times.

Deuterium is best suited for higher-voltage applications.

Xenon is another good choice, but for specific applications. Other gases, such as neon or mercury vapor, are also a good choice depending on the application.

Envelope Materials and Cooling Structures

An envelope would be made of glass for the low-poer versions. Ceramic envelopes are used for high-power thyratrons as they have superior thermal and mechanical strength. They can also withstand high internal temperatures and arch discharges.

High-power thyratrons also require cooling to function correctly. They can use either a forced-air or a liquid-cooling system to manage the heat generated during operation.

Ionization and Switching Mechanism

The thyratron operates on the principles of gas discharge and plasma dynamics. The result is that it acts as a triggered, non-linear switch.

Pre-ionization Process

A small continuous discharge is maintained near the grid or cathode to ensure having a reliable and consistent triggering. The result is that you have a constant source of initial ions and electrons, which makes the primary discharge initiation stable and faster.

Gas Breakdown and Conduction

At first, the anode voltage is high, but it is insufficient to cause gas breakdown. The grid is held at a negative voltage to repel electrons and prevent conduction.

When a positive trigger pulse is applied to the control grid, it injects electrons into the grid-anode gap. The work of these electrons is to accelerate and collide with gas atoms.

These collisions ionize the gas, thus creating a dense plasma of electrons and positive ions. The positive ions will then migrate towards the grid or cathode structure. This neutralizes the negative space charge, which allows the plasma to fill the tube.

The tube rapidly transitions to a highly conductive state, even with a very low voltage drop across it. This enables a large current pulse to flow.

Once the plasma forms, the grid loses its electrostatic control.

Hold-off Voltage Principles

The thyratron remains in the non-conducting state so long as the grid is negative enough to prevent the initial ionization cascade. So, the hold-off voltage is the maximum anode voltage the tube can withstand while in the off state.

Warm-up Requirements

Just like other thermionic devices, the thyratron tube cathode filament must be heated to an optimal operating temperature before a high voltage is applied to the anode. This practice ensures there is sufficient electron emission needed for a proper and stable operation. It also prevents cathode damage.

Electrical & Thermal Characteristics of Thyratron

Thyratron datasheets will have key electrical and thermal characteristics you should know about before working with them. Here is what you can expect.

| Parameter | Description |

| Peak anode voltage | This is the maximum forward voltage that is applied to the anode when the thyratron is non-conducting without spontaneously firing. |

| Peak pulse current | The maximum instantaneous current the glass tube can safely pass while in the conducting phase of the pulse. Keep in mind that the thyratrons can handle kiloamperes of current. |

| Anode delay | This is the time interval between applying the trigger pulse to the grid and the main current pulse starting at the anode. It is usually in the order of tens to hundreds of nanoseconds. |

| Jitter specification | A measure of the statistical variation in the anode delay time from one pulse to the next. Low jitter is vital for precise timing applications, such as radar or laser synchronization. |

| Recovery time | This is the minimum time required after a pulse for the gas to deionize sufficiently. This allows the grid to regain control and the tube to block the forward anode voltage again. |

Types of Thyratrons

Now that you know how does a thyratron work, let us look at the types. Thyratrons are largely categorized by the type of gas they use, which dictates the overall performance characteristics.

Classification by Gas Type

The gas type is a critical differentiator of how the thyratron works. It affects voltage handling, the switching speeds, and the operating temperature range.

The hydrogen/deuterium thyratrons are the modern standard for high-power pulsed applications such as radar and lasers. They offer very fast switching speeds, handle high peak currents, and remain stable over a wide range of temperatures.

Mercury vapor thyratrons were commonly used for industrial power control applications. They come with a low, stable voltage drop while in conduction and can handle high average currents. However, they are slow to deionize and require a specific warm-up time for vaporizing the mercury. The presence of toxic mercury has always been a concern in case the tube breaks.

Inert gas thyratrons were small; low-to-medium power thyratrons were used in triggering relays or simple sweep circuits. They are generally faster than mercury-vapor types but slower than hydrogen types.

Classification by Cathode Type

Thyratrons can also be classified based on how the electron source is supplied. Examples include the hot cathode and cold cathode thyratrons.

Hot-cathode thyratrons are the most common. They use a heated filament to produce thermionic emission of electrons. This is essential for controlled, reliable triggering and high-current handling. However, they need a warm-up period.

Cold-cathode thyratrons do not use a heated filament. They rely on a high-voltage pulse to initiate a discharge from the cold cathode. These types of thyratrons are extremely specialized and offer high-speed switching applications, such as detonation in nuclear weapons.

Classification by Envelope or Construction

Gas-envelope thyratrons are generally used for low- to medium-power applications. The glass used provides good insulation properties.

Ceramic/Metal thyratrons are for high-power applications. They are built for robustness, offering superior thermal and mechanical strength. They also incorporate liquid cooling structures.

Applications of Thyratrons

Thyratrons are quite robust and can provide high-speed, high-power switching. This is why it can work in different types of applications. Here are the top applications.

Radar Systems

The primary application of thyratrons was to modulate power in military and navigation radar transmitters. They can generate the high-voltage, high-current pulsed important for driving microwave sources such as magnetrons and klystrons with low jitter and precise timing.

Medical Radiotherapy

Thyratrons are also vital components in systems for cancer treatment. Their job is to power the linear accelerator used in the production of high-energy X-rays, which are used for destroying cancer cells.

Over 90% of the radiotherapy systems rely on the use of thyratron technology.

Particle Accelerators and Scientific Research

National laboratories and research institutions use thyratrons as reliable, high-power switches in different types of electrophysical devices. Such include beam injectors, experimental fusion power systems, and booster systems.

Industrial Applications

Thyratron circuits can also be used in harsh industrial environments. This is because they manage high-power switching for applications such as plastic recycling, diamond seeding, food sterilization, and mining processes.

Crowbar Circuits

The thyratrons can also be used in protection circuits such as crowbar circuits. In this case, when a fault conduction occurs, the thyratron rapidly fires to ground the power supply. This means diverting massive current surges and protecting the expensive equipment from damage.

Pulsed Lasers

Specific high-energy fast and solid-state lasers require rapid, high-voltage electrical pulses to excite the lasing medium. The thyratrons are essential to provide fast, reliable switching necessary for optimal laser operations.

Common Problems of Thryratons and How to Troubleshoot Them

Thyratrons are highly reliable if they are operated within their specified parameters. However, failures can occur because of gradual wear or circuit issues. Troubleshooting is important to get the thyratron working as expected.

Here are the common problems you may experience with thyratrons and how best to troubleshoot them.

Misfires or Erratic Firing

In this case, the thyratron fires spontaneously even without a trigger pulse. Also, the timing of the triggered pulse varies a lot. This indicates there are unstable internal gas conditions or circuit issues.

Symptom:

Having inconsistent pulse timing, system interlocks tripping on current faults, and unexpected output pulses.

Fixes

- Check the gas pressure and reservoir heating. Verify that the reservoir heater circuit is stable and maintain the correct temperature or voltage as specified by the manufacturer.

- Verify grid bias by ensuring the negative DC bias voltage on the control grid is stable. It should also be enough to hold off the anode voltage. Having a weak bias leads to spontaneous firing.

- Inspect the trigger pulse to ensure it has a consistent amplitude and a sharp, clean rise time. Jitters can be caused by a noisy or poorly shaped trigger signal.

- Ensure that the circuit design minimizes inverse voltage on the anode just after conduction. The high inverse voltage can cause instability and premature failure.

Tube Fails to Conduct or Has a Long Warm-up Delay

You may also notice that the thyratron does not fire when triggered or takes longer than normal to start conducting, even after the system is powered on.

Symptoms

There are no output pulses, the system fails to reach the operational state even after the warmup sequence, or there is a lack of internal orange glow from the filament.

Fixes

- Measure the filament voltage and current at the tube socket pins. If there is no power, check fuses, wiring, and the heater power supply.

- Check for cathode depletion as cathode coating erodes over many hours of use. Cathode depletion reduces electron emission. When this happens, it is an end-of-life sign for the thyratron. It is best to replace the tube.

- Confirm that the trigger pulse is reaching the control grid with sufficient amplitude. Use an oscilloscope for checking.

Reduced Performance or Short Lifetime

The tube can be working, but it delivers less power. Also, the pulse shape degrades, or the tubes fail prematurely, as compared to the expected lifespan.

Symptoms

There is a loss of peak power, visual signs of electrode erosion, increased required reservoir voltage over time, and a distorted pulse shape.

Fixes

Look for a white coating inside the tube envelope. This indicates a completely failed tube and an air leak. The normal getter color is silver/black/grey.

Analyze the operating parameters. A thyratron may operate outside its maximum ratings. Review the circuit design and operational logs.

Excessive heat may lead to faster electrode erosion. Verify that the cooling systems are functioning correctly and that airflow is not blocked. Well, overcooling could still be an issue as it can disrupt the gas pressure.

Ensure that the high current connections around the thyratron are symmetrical. This prevents magnetic forces from causing uneven current density and localized erosion.

Arcing/Internal Flashing

There is visible internal arcing around the elements rather than the intended main discharge. System trips mostly accompany this.

Symptoms

Expect to come across audible arching sounds, flashing lights inside the tube away from the normal discharge path, and the power supply tripping off.

Fixes

- Check for contamination. Vaporized electrode material can be deposited on internal ceramic insulators over time. This leads to leakage paths. In this case, tube replacement is the best solution.

- Reduce the anode voltage. It could be that the applied voltage is too high for the tube’s condition or current gas pressure.

- Flashing may occur if there is high voltage applied before the cathode is fully heated. Ensure that the warm-up delay timer is functioning correctly.

Conclusion

Thyratrons are robust, triggered switches that leverage gas ionization to manage electrical loads that would damage conventional semiconductors. They are built to last and excel in environments that demand rapid delivery of massive peak currents and high voltages. Despite having some limitations, the thyratron technology is still important today in high-precision applications.

Please send RFQ , we will respond immediately.

Frequently Asked Questions

What gases are used in the thyratrons?

The most common gases include hydrogen for its fast rise time, deuterium for high voltage capability, and xenon for stable high energy, but may have slow switching capabilities.

Why are thyratrons still preferred over semiconductors in some applications?

It is because thyratrons can handle extremely high voltages, ultra-fast pulse rise times, harsh electrical conditions, and massive peak currents. Many semiconductor devices may not handle this type of combination in high-energy applications.

Why is a warm-up period required in a thyratron?

The filament must heat the cathode for it to emit electrons and stabilize the gas pressure. So, the warm-up period is essential to ensure there is reliable triggering and also to prevent damage.