Understanding Accelerometers: Working Principle, Use Cases, and Future Trends

Author:admin Date: 2025-07-11 08:53 Views:500

- Introduction

- How Does an Accelerometer Work?

- Types of Accelerometers

- Key Applications of Accelerometers

- How to Choose an Accelerometer for a Project

- How to Interface Accelerometers with Microcontrollers

- Accelerator Installation and Mounting

- Challenges and Limitations of Accelerometers

- Gyroscope Vs Accelerometer: Know the Difference

- Conclusion

Introduction

An accelerometer is a type of device used to measure acceleration. This is the rate of change of velocity. It works by detecting the changes in motion, vibrations, and the force of gravity. Basically, it quickly determines the change in an object’s speed or direction.

Accelerometers are important in various industries. You are likely to come across them in smartphones, automotive, aerospace, gaming, medical, and many others.

How Does an Accelerometer Work?

An accelerometer sensor works by measuring the acceleration forces. This is where it detects the force exerted on a mass and converts that force into an electrical signal. This signal is used to determine the amount of acceleration or the rate of change of velocity.

Types of Accelerometers

There are many types of accelerometers on the market. Each may have a different working principle, which makes it suitable for certain applications over others. Here is what to expect.

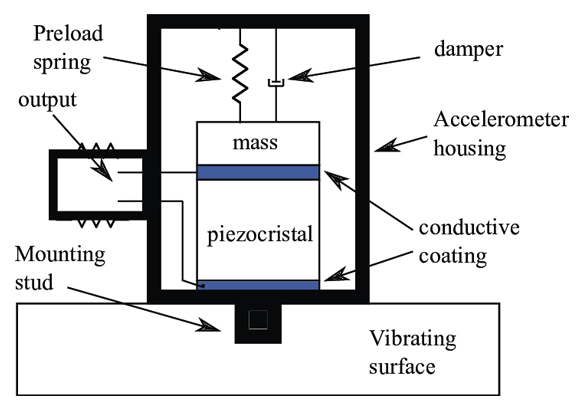

Piezoelectric Accelerometers

These accelerometer sensors are built with piezoelectric materials such as ceramics and crystals that can generate an electric charge if they are subjected to a mechanical stress due to acceleration.

These accelerometers offer high frequency response, wide dynamic range, and a robust construction. It is because of such they are highly sensitive and accurate. You can use them for applications such as seismic measurements, crash tests, and vibration analysis.

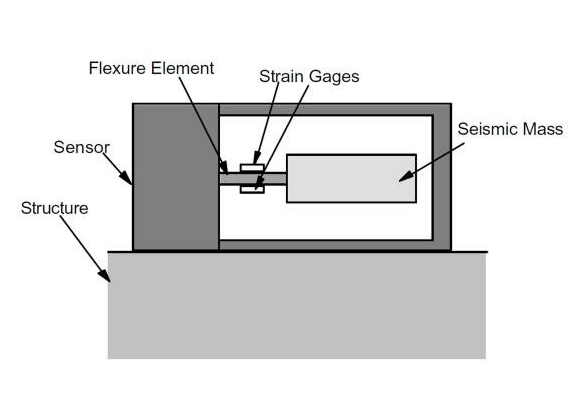

Piezoresistive Accelerometers

In this case, the accelerometers are built with materials whose electrical resistance is altered by mechanical stress. The change in resistance is what is used to measure acceleration.

These accelerometers offer a wide measuring range compared to the piezoelectric accelerometers. However, they may need temperature compensation and may struggle with very weak signals.

They are mostly recommended for measuring slowly changing signals. This makes them useful for applications such as weapons testing and crash testing.

Capacitive Accelerometers (MEMS)

In this case, the accelerometer uses microelectromechanical system to determine the acceleration. Acceleration makes a proof mass to move, which in turn changes the capacitance between the capacitor plates.

These accelerometers tend to be small in size, low cost, and are suitable for measuring static acceleration and low-frequency vibrations.

There may be other categorization methods for accelerometers, but the ones mentioned above are the primary ones you will encounter in various applications.

Key Applications of Accelerometers

Now that you know more about what is an accelerometer, let us look at the most common applications of the same.

Consumer electronics such as smartphones and tablets are the biggest users of accelerometers. They are used to determine functions such as screen rotation, gesture recognition, and gaming. The same can be found in wearable devices and digital cameras.

The automotive sector can also benefit from the use of a 3-axis accelerometer. This is where it can be used for airbag deployment when it detects sudden deceleration in a collision. Other applications include anti-theft systems and vehicle stability control.

Aerospace and aviation industries also use triaxial accelerometers in their navigation systems. These are crucial components in the inertial navigation systems key in providing orientation and position information. The same is also important for spacecraft and satellites, as well as for flight testing.

Industrial applications, such as vibration monitoring, require accelerometers to help detect and analyze vibrations in machines. This is crucial for enabling predictive maintenance and preventing potential equipment failure in the future.

Additionally, accelerometers are commonly used in research, such as biomechanics studies, where they are employed to investigate human movement and the mechanics of motion. Other applications include motor control research and physical activity research.

How to Choose an Accelerometer for a Project

Choosing a three-axis accelerometer or any other type should not be hard now that you know more about it. Below are some features to consider.

Sensitivity – look at how sensitive the accelerometer is to the changes in acceleration. Also, ensure that the signal-to-noise ratio of the accelerometer is suitable for your application.

Bandwidth – this determines the frequency range that the accelerometer works. Look at your application and pick the accelerometer that meets your needs in this regard.

Noise level – Consider the residual noise level of the sensor, as it can impact the accuracy and precision of its acceleration measurements.

Mounting – the mounting method can vary from one type of accelerometer to the other. Common examples include adhesive and magnetic mounting. Ensure you select the correct mounting to achieve optimal performance at all times.

Type of accelerometer – examine the various types available and select accordingly. We have the piezoelectric (PE), capacitive MEMS, and piezoresistive types of accelerometers. Each has a unique set of applications and limitations.

Environmental conditions – consider how temperature, humidity, and the presence of electromagnetic fields can impact the accelerometer’s performance. This helps you select the right accelerometer sensor that can withstand the environmental conditions in which it will be used.

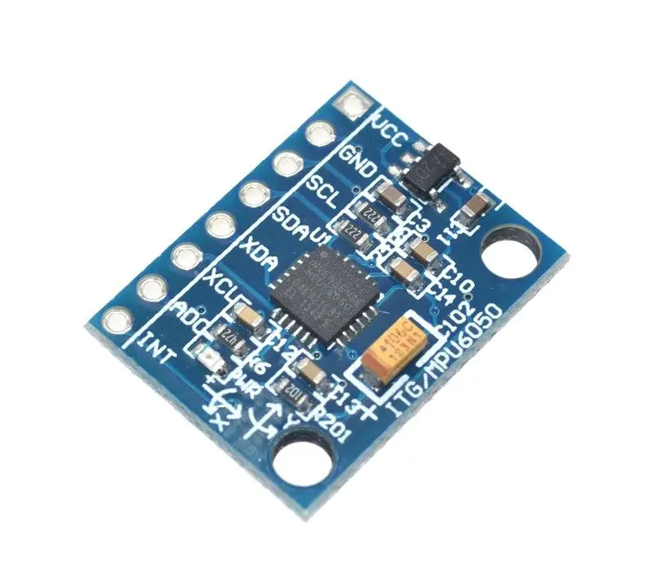

How to Interface Accelerometers with Microcontrollers

Yes, it is possible to use a three-axis accelerometer with a microcontroller. Here is the process of how you would interface an accelerometer with a microcontroller.

Identify the interface

Accelerometers mostly use either the I2C or SPI interface for communicating with the microcontroller. These specific interfaces will be in the accelerometer’s datasheet to determine how best to use it.

Power and Ground

Connect the accelerometer’s VCC pin to the power supply of the microcontroller and the accelerometer’s ground to the GND pin.

Data Connections

You can use the I2C for data connections with the microcontroller. Connect the SDA and SCL pins of the accelerometer to the corresponding SDA and SCL pins of the microcontroller.

If it is an SPI connection, connect the MISO, MOSI, and SCK pins of the accelerometer to the corresponding pins on the microcontroller.

Microcontroller Configurations

Starting with the I2C configuration, proceed to configure the I2C module to communicate with the accelerometer’s I2C address. Refer to the accelerometer’s datasheet to determine its I2C address.

The SPI configuration has a similar method where you configure the SPI module to easily communicate with the accelerometer. This includes setting the clock speed, mode, and data order.

Reading Data

Use the I2C functions to send read commands to the accelerometer and still retrieve the data from the right registers. The same applies to the SPI setup.

Accelerator Installation and Mounting

The installation of accelerometers is not hard. It comes down to what type of mounting is provided with the sensor. In this case, we will examine the general process of mounting an accelerometer. Here are the steps to follow.

1. Prepare the surface

Follow the manufacturer’s documentation to understand where best you can install the accelerometer. If the unit requires physical mounting, consider using tools such as screws, cables, or any other recommended for mounting the accelerometer.

2. Physical mounting

Hardware accelerators need to be mounted onto a compatible bracket or riser. Ensure that it is securely seated and clicks into place to avoid any movement that might cause it to be unreliable.

As for the software-based accelerators, there will be instructions on how to install and configure them to work with the target system.

3. Cabling and connections

You may have to connect power cables to the accelerometer and the system board. Additionally, data cables are necessary to transfer information from the sensor to a computer for analysis and visualization.

4. Final steps

You may need to install necessary covers to provide protection and cooling where possible. Turn on the system and check if it performs as expected; adjust settings as necessary for optimal performance.

Challenges and Limitations of Accelerometers

Accelerometers are quite versatile in terms of applications and performance. However, they also tend to have challenges and limitations. Here are some of them.

Sensitivity to Noise and Drift

Accelerometers can be susceptible to noise, which also interferes with accurate measurements. Expect the internal components to degrade with time, making it unreliable in terms of giving you the best readings.

Gravity Influence

The Earth’s gravitational force is another significant factor when measuring across the sensitive axes of the accelerometer sensor. It is therefore important to correct for the gravitational influence, but it can also be challenging.

Battery Life and Data Processing

Accelerometers often have limited battery life, particularly when used in cold temperatures. This can be a problem when used for long-term studies. Additionally, raw data from an accelerometer can be challenging to interpret without the appropriate software and algorithms.

Placement Issues

The placement of the accelerometer affects its overall accuracy. This is why different placements may lead to different readings, making it difficult to compare data across these points. It is therefore essential to accurately determine where they are most effective.

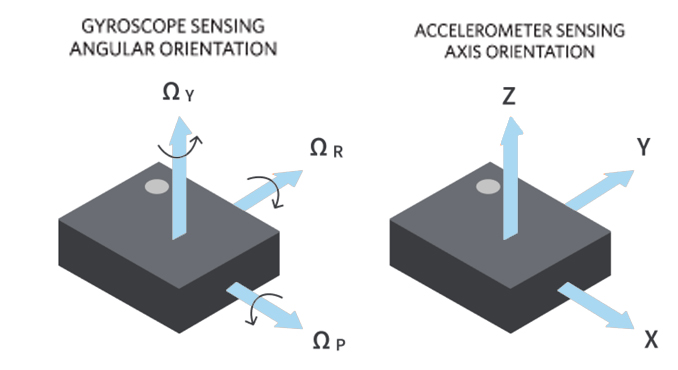

Gyroscope Vs Accelerometer: Know the Difference

Both accelerometers and gyroscopes are motion sensors, but they are designed to measure different things.

Accelerometers are used for measuring linear acceleration in one or more axes. Typically, it can measure acceleration in three axes. For example, you will find accelerometers being used in phones to determine the orientation of the phone, the steps in a pedometer, or detecting a car’s impact to release the airbags.

Gyroscopes, on the other hand, are used for measuring angular velocity or rotational speed around one or more axes. For example, stabilizing video footage on a camera, controlling the flight of drones, and enabling virtual reality experiences.

Gyroscopes can be affected by drift and are less sensitive to linear acceleration than accelerometers.

Conclusion

We have seen the importance of accelerometers in measuring acceleration and using this information to impact different applications. There are several types of accelerometers, each having a different working principle and suitable applications. This is important to consider the next time you are looking for an accelerometer for your project. Expect accelerometer sensors to be suitable for various applications, including automotive, smartphone, aerospace, and industrial settings. You should always choose appropriately depending on the recommended use of the accelerometer type.

Please send RFQ , we will respond immediately.

Frequently Asked Questions

Are accelerometers compatible with Arduino or Raspberry Pi?

Yes. Accelerometer modules often work with microcontrollers such as Arduino and Raspberry Pi. Make sure the microcontroller has the right interface that can work with accelerometers. This makes it easy to integrate them into DIY projects.

What is a 3-axis accelerometer crucial for?

When we say 3-axis, it means the accelerometer can measure acceleration in three dimensions: X, Y, and Z. This provides complete information about the motion and orientation space. That is how accelerometers come in handy for drones, wearable tech, and smartphones.

How accurate are accelerometers?

The accuracy of accelerometer sensors largely depends on the quality and type of sensors. MEMS accelerometers in consumer devices are known for their accuracy in general use. For industrial and aerospace applications, you need accelerometers designed to offer the higher precision required for such applications.