Ceramic Potentiometers: How They Work and Applications

Author:admin Date: 2026-02-02 03:39 Views:31

- Introduction

- Key Components of Ceramic Potentiometers

- Electrical and Mechanical Characteristics of Ceramic Potentiometers

- Types of Ceramic Potentiometer

- Pros and Cons of Ceramic Potentiometer

- Applications of Ceramic Potentiometers

- How to Choose the Right Ceramic Potentiometer

- Common Problems and Troubleshooting of Ceramic Potentiometers

- Conclusion

Introduction

A ceramic potentiometer is a highly stable variable resistor that incorporates ceramic materials to achieve superior thermal and environmental performance. The ceramic potentiometers differ from the standard potentiometers based on the power handling, thermal stability, durability, and the environments they are used in.

Someone would ask, why are ceramic materials used?

- They offer high termal stability

- The material comes with better environmental resilience

- Offers low resistance drift

- Comes with better mechanical durability

Key Components of Ceramic Potentiometers

These components determine how well the ceramic potentiometer works. Here are the key components.

Ceramic Substrate

This is the base of the potentiometer and it is made of high-purity alumina. This is what provides the mechanical support and high thermal conductivity for dissipating heat.

Resistive Track

This is a thick-film later created through printing a specialized paste, which is a mixture of organic binders, glass powder, or metal oxides, onto the substrate. It is sinterted at temperature between 800°C and 1000°C.

Wiper or Brush

This is the movable contact mostly made of a precious metal alloy that slides across the resistive track to adjust the output voltage.

Terminals

You will get three metal leads. Two of them are connected to the resistive track ends while the center terminal is connected to the wiper.

Electrical and Mechanical Characteristics of Ceramic Potentiometers

Ceramic potentiometers come with interesting electrical and mechanical characteristics which determine their applications. Here is what you should know.

Resistance Range and Tolerance

The potentiometer comes with a broad range for resistance. It spans from 10 ohms to 5 mega ohms. We can also say the same in terms of tolerance. It is designed to be enough to work for most applications.

You can also expect infitire resolution as well. This is because of the resistive track which offers virtually infitire resolution which is important for extremely fine adjustments.

Power Rating and Heat Dissipation

The ceramic potentiometers come with high power density. Expect to get high thermal conductivity as well, this enables them to dissipate heat faster than carbon or plastic bases.

The typical rating of cermet potentiometers is between 0.5W and 2W. However, the industrial grade models can handle 5W or even more.

Temperature Coefficient and Thermal Stability

The ceramic potentiometer exhibit very low temperature coefficient of resistance as compared to traditional potentiometers.

Because of such a feature, they can function reliably across a wide range of temperature spectrum. They can still maintain stable resistance values at th extremes.

Noise Characteristics and Signal Stability

The ceramic potentiometers have minimal electrical noise generated during wipre movement.

As much as they might produce more current noise than the wirewound types, their overall signal stability is still superior than carbon film alternatives. This is because of the consistent grain structure of the cermet track.

Mechanical Lifespan and Durability

The ceramic layer of the potentiometer is exceptionally hard. It can reach hardness levels of 1500HV. This is important to reduce the physical wear from the sliding wiper.

Standard ceramic potentiometers have up to 200,000 cycles. If you get the specialized versions, this goes up to 2 million cycles. They are commonly used in industrial applications.

The materials used in making these potentiometers are chemically inert. This makes them resistant to oxidation, corrosive chemicals, and oxidation.

Types of Ceramic Potentiometer

You are likely to come across multiple types of ceramic potentiometers depending on categorization. Here is what you can get in the market right now.

- Single-Turn Ceramic Potentiometers

These are ceramic potentiometers with a rotational range of 270° to 300°. They offer quick adjustments where high resolution is not necessary. Such include basic user-interface controls and simple motor speed regulation.

They are compact while at the same time cheaper than the multi-turn models.

- Multi-turn Ceramic Potentiometers

In this case, they require multiple rotations. This can be 10, 20, or 25 turns to travel the full resistance range. They come with a helical mechanism or worm-gear to drive the wiper.

Since they spread the resistance over several turns, it allows for ultra-fine adjustment and higher resolution as well.

We recommend them for applications that need meticulous calibration for example lab instruments, industrial automation systems, and aerospace sensors.

- Linear vs. Logarithmic Types

In the linear type, resistance changes proportional to the wiper position. In such as a case, 50% rotation means 50% resistance. Expect to find them in precision measurement and most industrial controls.

Logarithmic types have resistance changing exponentially to match the human hearing perception. These are common in professional audio mixes and studio equipment. This provides you with a natural-feeling in volume increase.

- High-Power Ceramic Potentiometers

These leverage the high thermal conductivity of alumina substrate to handle high power loads. They are rated for up to 60W at 500C, this is higher than what you get with the standard 0.5W carbon film variants.

As for applications, they are used in power supplies, industrial heating control, and lab equipment as well.

- Precision and Trimming Ceramic Potentiometers

Trimming or trimpot potentiometers are small board mounted potentiometers used for one-time calibration and sometimes set-and-forget adjustments.

As for precision models, they are designed for high-frequency adjustments and maintain extreme stability.

Pros and Cons of Ceramic Potentiometer

Ceramic potentiometers generally provide robust solutions when used. Below are the pros and cons of such potentiometers.

Advantages

- The alumina substrate in the ceramic potentiometers offers high thermal conductivity. This allows them to dissipate heat more efficiently. This leads to higher power ratings and stable operation even at temperatures up to +125°C.

- The resistive track on the ceramic potentiometer is hard. This improves the wear resistance, with the Vickers hardness estimated to be 1500HV. So, there will be minimal metal wiper wear. These components are expected to have a lifespan of over 100,000 cycles.

- Ceramic materials are chemically inert. This makes those components highly resistant to oxidation, solvents, corrosion, and moisture.

- The combination of infinite resolution and high heat tolerance makes ceramic potentiometers suitable for high-power and precision applications. They are used to bridge the gap between durable power applications and high-precision calibration needs in the aerospace and medical fields.

Limitations of Ceramic Potentiometers

- Ceramic potentiometers use specialized materials such as alumina, palladium, and ruthenium, combined with complex high-temperature manufacturing processes, which make them more expensive.

- They are not ideal for compact designs, as they require larger form factors to achieve higher power ratings than carbon film trimmers.

Applications of Ceramic Potentiometers

Ceramic potentiometers are generally used in demanding applications that require stability and reliability. The applications rely on their superior thermal resistance combined with mechanical durability, unlike traditional potentiometers. Here are the primary uses of ceramic potentiometers.

Industrial Control Systems

Ceramic potentiometers are key to providing robust solutions for managing analog signals and controlling equipment across different industrial settings.

You can use them for motor speed control, enabling easy adjustment of motor speed in conveyor belts, robotic systems, and manufacturing lines.

They are also used in process control to monitor and control variables such as pressure and temperature.

Power Supplies and Voltage Regulation

This is where ceramic potentiometers are used for their stability in power circuits. Expect stable voltage dividers if ceramic potentiometers are used in microcontrollers or analog circuits.

They can also be used in calibration. This is where cermet trimmers are used to fine-tune voltage thresholds and power circuit gain settings.

Ceramic potentiometers can dissipate heat quickly, making them well-suited for managing circuits, such as high-brightness LED systems.

Audio and Signal Conditioning Circuits

Low electrical noise and precise adjustments make them a key component in audio and signal processing equipment.

Expect them to be used in high-fidelity audio systems, professional mixing controls, and amplifiers to provide noise-free volume, balance, and smooth tone adjustments.

They are also common in oscilloscopes and signal generators for precisely tuning signal levels.

Automotive and Aerospace Electronics

Ceramic potentiometers can withstand extreme temperatures, environmental factors, and vibrations. That is how they are key in transport applications as well.

You can use them in ECUs and battery management systems to calibrate critical sensor signals. This ensures accurate data for engine management and safety features.

Potentiometers are also standard in aircraft flight control systems and simulators. This helps in measuring the position of control surfaces, where reliability is critical.

How to Choose the Right Ceramic Potentiometer

Choosing ceramic potentiometers should not be hard when you have the right guide. Here are the tips to keep in mind when choosing the best ceramic potentiometers.

- Resistance value and tolerance selection

The total resistance is essential to consider to ensure the potentiometer fits your application.

Look at the tolerance as well. Make sure that you choose the proper tolerance, especially for precision applications.

Look at the resolution as well. This is key if you have to make microscopic adjustments. In such a case, pick a multi-turn model that offers significantly higher resolution than single-turn models.

- Power rating

You should always follow the 50% rule when choosing a potentiometer. This means getting a ceramic potentiometer with double the power rating of your circuit will dissipate.

Power ratings are mostly specified at 700C. So, if your device operates in an enclosure reaching temperatures of 1000C, then look at the derating curve from the manufacturer as the allowable power will quickly drop to 40 – 60%.

If you have applications for small-motor control or high-power LED dimming, ensure the ceramic potentiometer is rated for 2W to 5W.

- Temperature and environmental factors

For outdoor and industrial use, it is best to select IP65 or IP67-rated sealed units. This prevents dust, moisture, and cleaning solvents from getting into the housing.

Look at the temperature coefficient as well. If the device will be in fluctuating climates, then pick a model with a low TCR. This prevents the resistance from drifting as the unit warms up.

You are likely to get many washable ceramic potentiometers. It is important to use the right cleaning methods, even if it includes chemicals.

- Adjustable style, mounting, and size

For mounting type, you have panel mount, surface mount, and through-hole. The through-hole type is best suited for high-vibration environments. Surface-mount technology is used in modern, compact, high-density PCBs.

You also have to consider the adjustment orientation. Choose between the top-adjust and side-adjust depending on the installation.

- Logarithmic vs. Linear Taper

In a linear taper, it is used for all calibration and measurement tasks when a 10% turn equals a 10% change in resistance.

As for logarithmic or audio taper, it is used for precise volume control. This is because human hearing perceives sound logarithmically. Using a linear potentiometer for volume can cause the sound to jump from quiet to loud with just 10% of the rotation.

Common Problems and Troubleshooting of Ceramic Potentiometers

While ceramic potentiometers are built for extreme durability, they can still have a few performance issues. Here is what to expect.

Noise and Signal Fluctuations

Electrical noise in ceramic potentiometers is measured as Contact Resistance Variation (CRV). This is when there is a sudden jump in voltage or scratchy audio output whenever the knob is turned.

This happens because oxidation or microscopic debris on the meral wiper causes intermittent contact.

In high-vibration applications, fretting corrosion can occur when the wiper vibrates against the track.

Solution:

Make sure to use a specialized contact cleaner spray to flush the internal track. If the unit is sealed, it is best to replace it, as such noise indicates an internal mechanical failure.

Resistance Drift

Resistance drift happens when the potentiometer’s value changes without even moving the wiper.

A recently calibrated circuit will no longer output the correct voltage after just a few days. The leading causes for this include thermal overload and humidity.

Exceeding the power rating causes the glass frit in the ceramic potentiometer to crack or expand. This alters the resistance permanently.

As for humidity, the non-hermetic models can absorb moisture into the substrate over time. This creates parasitic parallel resistance paths.

Solution

Make sure the device operates within its derating curve. This is usually 50% of its rated power for temperatures above 700C.

Mechanical Wear and Failure

In this case, the shaft feels loose and does not turn smoothly. Sometimes it can feel physically stuck.

The leading causes for this include substrate fracturing and wiper deformation.

In substrate fracturing, ceramics can be brittle. So, excessive force during installation, or sometimes a sharp mechanical shock, can crack the substrate. This leads to a permanent open circuit.

Also, if a potentiometer is adjusted too rapidly with high-torque tools, the precious-metal wiper can snap or bend.

Solution

Make sure to use the correct size screwdrivers for trimpots and also avoid exceeding the recommended stop torque, depending on the application and potentiometer.

Conclusion

Ceramic potentiometers are essential in a wide range of applications, including industrial, medical, and aerospace. They are also suitable as a vital middle ground between low-cold and low-durability carbon-film models and high-power wirewound variants. Always make sure to review the features your circuit requires before selecting the right ceramic potentiometer.

Please send RFQ , we will respond immediately.

Frequently Asked Questions

How do ceramic potentiometers work?

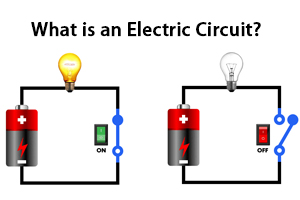

A ceramic potentiometer works as a voltage divider. When the adjustment screw is turned, the wiper moves long the ceramic resistive track. This act changes the resistance between the controlling voltage and the termines. This is also what determines the output voltage.

Are there limitations to ceramic potentiometers?

Some of the limitations include higher cost compared to carbon potentiometers, larger size especially for high-power designs, and less common for ultra-compact consumer devices.

What is the difference between wirewound and ceramic potentiometers?

Ceramic potentiometers are designed to provide smooth resistance changes and a better signal stability. As for wirewound potentiometers, they are designed to handle high power but might introduce step-like resistance changes and electrical noise in some sensitive circuits.