Inclinometer: Types, Applications, and Installation Guide

Author:admin Date: 2025-12-16 07:51 Views:98

Introduction

An inclinometer is also known as a tilt sensor. It is an instrument used for measuring the angle of a slope, tilt, or elevation of a surface or object relative to the direction of gravity. Expect such measurement to be in degrees, percentages, or specific engineering units, depending on the application.

How an Inclinometer Works

Inclinometers have internal sensing elements that change position with the angle and convert that change into a measurable electrical signal. The most common types of inclinometers use the Micro-Electro-Mechanical Systems or MEMS technology.

MEMS Inclinometer Working Principle

In this case, the primary mechanism depends on a tiny, internal sensing element whose functionality is affected by gravity.

The sensor has a movable electrode or small proof mass that is suspended by spring elements between fixed electrodes.

Whenever the sensor is held level, the mass is in a baseline position, and a specific electrical capacitance can be measured between the electrodes. In this case, gravity acts as the fixed reference point for the other measurements.

As the inclinometer tilts, the force of gravity causes the suspended mass to shift its position as well relative to the fixed electrodes.

A change in the mass’s position results in a change in electrical capacitance. This is measured by internal circuity. A microcontroller processes this electrical signal and converts it into an angle of inclination, such as displayed as percentage points or degrees.

Types of Inclinometers

Now that you know what is an inclinometer, we can focus on the types. Inclinometers are generally categorized depending on their measurement capability, operational method, and installation method. Let us look at each type keenly.

By Operational Method

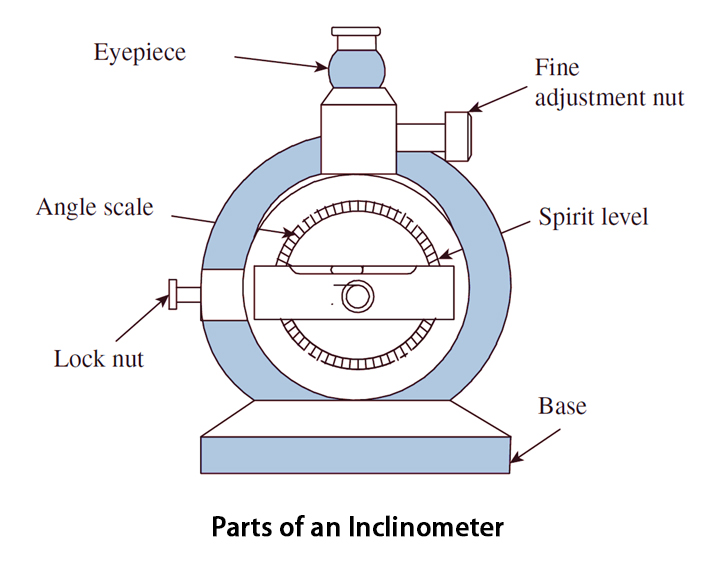

Manual Inclinometers

These are the most basic devices that rely on simple physical principles, such as a spirit level or a suspended pendulum that points to a marked scale to indicate the angle. They require an operator to take the reading. Expect them to be simple and cost-effective.

Digital or Electronic Inclinometers

These inclinometers use electronic sensors. This includes MEMS accelerometers that provide highly accurate, instant digital readings. They will feature a digital display, data logging, and Bluetooth connectivity for ease of integration with other systems.

By Measurement Capability

Single-Axis Inclinometers

These sensors can measure tilt or slope along only one plane, for example, the roll angle when they are mounted horizontally. Such inclinometers are useful for monitoring movement in a specific or predictable direction, such as the deformation of a retaining wall.

Dual-Axis Inclinometers

These are used to measure angles simultaneously along two perpendicular axes, X and Y. They are often referred to as pitch and roll. This setup is vital for applications whose movement can go in any direction. For example, monitoring the stability of a vertical rod or a platform leveled on uneven surfaces.

3D Inclinometers

These are advanced systems that can monitor the movement in three dimensions: X, Y, and Z axes. They are often combined with settlement measurements.

By Installation Type

Traversing Inclinometers

These are portable probes that can be lowered or pulled through a permanently installed guide case in a borehole or structure. The reasons are then taken at fixed intervals to build a profile of movement along the entire length.

In-Place Inclinometer (IPI)

These are sensors interconnected and permanently installed within a casing so as to provide continuous, real-time monitoring of movement. These are important for critical applications that require immediate alerts, which include dam safety systems or landslide monitoring.

By Operating Environment

Static Inclinometers

Used in stable environments or for measuring tilt on stationary objects, including monitoring solar panel alignment or the health of a bridge. These accelerometers are used to precisely measure the effect of gravity.

Dynamic Inclinometers

Designed for use in mobile applications and are subject to rapid movement, vibration, and shock. These systems integrate gyroscopes and accelerometers to differentiate actual tilt from movement-induced acceleration accurately. Expect to find them in heavy machinery such as excavators and cranes.

Single-Axis vs Dual-Axis Inclinometers

The main difference is that a single-axis inclinometer measures the angle of tilt in one plane while a dual-axis inclinometer measures the tilt in two planes simultaneously. This offers a more complete pick of an object’s orientation.

Here is a comparison table to help you understand the differences in more detail.

| Feature | Single-axis inclinometer | Dual-axis inclinometer |

| Measurement axes | One axis | Two perpendicular axes |

| Data collected | Linear or planar tilt information | A comprehensive view of orientation in a 3D space |

| Cost and Complexity | Simpler in design and is more affordable | More complex and thus more expensive |

| Applications | In places where movement is predictable along a single plane, such as field leveling or monitoring a retaining wall | Applications where movement may occur in any direction, such as cranes |

| Installation | The installation method can determine whether it measures pitch or roll | It is used to measure both pitch and roll regardless of the orientation. |

Applications of Inclinometers

Inclinometers are quite versatile in terms of applications. You are likely to find them in many areas where precise angle measurement is important. Some of the key applications include:

Geotechnical and Civil Engineering

Inclinometers are installed in boreholes to monitor ground movement in dams, natural slopes, and embankments. They are vital for providing early warnings for landslides and potential collapse.

They can also monitor the stability and settlement of critical infrastructure in high-rise buildings, tunnels, or bridges for signs of fatigue or deformation.

During deep urban excavations, inclinometers can track subtle ground shifts to ensure that nearby existing buildings and utilities remain stable and undamaged.

Expect them in the dam and retaining wall safety. This is because they measure internal soil shifts caused by seismic activity or water pressure. Such information helps the engineers plan for maintenance and reinforcements.

Construction and Mobile Machinery

Inclinometers are essential for the safe operation of heavy-duty equipment like boom lifts, excavators, and cranes. They can automatically adjust the base or warn operators if the safe tilt limits are approached.

Inclinometers also offer real-time data on the angle of crane booms or excavator arms. The result is that the loads are positioned accurately and safely.

You will also find inclinometers in the agricultural and construction sectors. They are widely used to maintain consistent angles for tasks such as precise crop planting, harvesting, or road paving, ensuring a level surface.

Other Applications

Static inclinometers are common in the renewable energy sector, where they help optimize the angle of solar panels so as to maximize sunlight exposure and monitor the tilt of wind turbine towers for stability as well.

Inclinometers are also available on floating oil rigs and shots to correct the pitch and roll. The result is more stability and precise positioning of equipment such as satellite antennas or drilling machinery.

Medical equipment also uses inclinometers, which are integrated into surgical tables and physical therapy devices. In this case, they monitor the patient’s positioning and accurately track joint range of motion.

How to Choose an Inclinometer

There are several factors to consider when it comes to choosing an inclinometer. Here is what you can consider when picking one.

Static vs. Dynamic Environment

Static inclinometers are the best for applications with very slow movement or stationary objects. This includes solar panel positioning or bridge alignment. You should find them highly accurate in stable conditions.

Dynamic inclinometers are the best for environments with significant movements such as shock, vibration, and more. That is why you will come across them in construction machinery or robotics. Having a gyroscope helps filter out noise to provide stable and real-time title readings.

The Number of Axes

You will normally get single-axis and dual-axis inclinometers. Single-axis inclinometers measure tilt along a single plane and are suitable for straightforward tasks where the movement is predictable—for example, a vertical wall.

The dual-axis inclinometers measure the tilt along two perpendicular axes simultaneously. This provides a comprehensive assessment of the multi-directional movements, ideal for platform leveling or complex structural monitoring.

Measurement Range and Accuracy

Of course, these two are essential for the success of an application. Start by selecting an inclinometer with a measurement range that covers the maximum expected tilt in the application.

Secondly, determine the required accuracy and resolution. High-precision applications, such as long-term monitoring and lab use, may require higher resolution and sensitivity. These come at a higher cost.

Environmental Conditions

Assess the operating environment to understand factors such as temperature fluctuations, vibration, water, and humidity.

Choose the inclinometer type that has the appropriate Ingress Protection (IP) rating. For example, you will come across IP65 or IP67. Still, ensure it has a wide temperature operating range to ensure durability and reliable performance.

Output Type

Ensure there is compatibility with your existing control or data logging system. The common output types include analog and digital.

Analog inclinometers are best suited for simple systems or long-distance transmission. The digital inclinometers, on the other hand, are for modern automation, have strong anti-interference capabilities, and can connect with multiple sensors.

Maintenance and Troubleshooting

Routine maintenance is necessary to ensure consistent performance and minimize the risk of system failure. Here are the best maintenance tips to keep in mind.

- Regular cleaning, such as wiping down the probes, cables, and the external housing, is recommended. The aim is to remove debris, dirt, and moisture that affect the inclinometer’s performance.

- Periodically, clean and lubricate the O-rings and the bearings on the probe wheels. Make sure to use the appropriate waterproof grease or light oil to ensure smooth movement within the casing and further prevent corrosion.

- You should always store the equipment in a dry, dust-free environment, away from direct sunlight and extreme temperatures. Storing probes in a vertical position for extended periods is also recommended.

- If a system has rechargeable batteries, make sure they are recharged even when the sensor has to be stored long-term. This is to maintain capacity and improve life expectancy.

- Regular recalibration is recommended every 6 to 12 months or if there is a significant physical shock.

Troubleshooting Common Issues

| Problem | Potential Causes | Solutions |

| No reading or connection issues | Loose cable connectionsDead batteriesIncorrect software settings | Check all physical connections, making sure they are tight.Verify the batteries are charged. Check the device manager for the correct COM port usage |

| Inaccurate or drifting data | Temperature fluctuations Sensor bias shiftDepth positioning errors | Allow the probes to stabilize at ambient temperature.Use the standard two-pass survey method for sensor bias shift.Ensure the same depth reference points are used for all readings. |

| Probe gets stuck | Debris or dirt in the casingCasing damage or twistingNon-parallel grooves | Do not force the probe. Remove the debris or water from the case with a pump. If the casing is damaged, you might need repairs or replacement. |

| Water entry | Damaged O-rings or insufficiently tightened cable connectors | Inspect the O-rings regularly for nicks or cuts and replace where necessary. Ensure all connections are tightened correctly to compress O-rings effectively. |

Conclusion

The inclinometer is an essential, versatile instrument used in many safety-critical applications. This includes monitoring ground safety stability to ensure safe operation of heavy machinery. You will also come across different types of inclinometers. They are all designed to work in various environments, so make sure to choose the one that best suits your environment. Make sure the inclinometer is well-maintained by following the tips above to ensure optimal performance.

Please send RFQ , we will respond immediately.

Frequently Asked Questions

Is there a difference between an inclinometer and a tilt sensor?

A tilt sensor is a basic form of an inclinometer. It is used for simple and limited range measurements. As for inclinometers, they provide higher accuracy, continuous angle data, and wider measurement ranges. This makes them suitable for professional and industrial use.

How accurate can inclinometers be?

Inclinometer accuracy largely depends on the application and sensor type. High-quality inclinometers will have accuracy levels as fine as ±0.001°, while the standard models’ accuracy levels range from ±0.01° to ±0.1°.

How can you calibrate inclinometers?

Inclinometers can be calibrated via factory calibration, field calibration with the help of reference surfaces, zero-point adjustment, and temperature compensation. Regular calibration is recommended to ensure long-term measurement reliability.