How Integrated Circuits Work: Structure, Examples, and Future Trends

Author:admin Date: 2025-08-15 02:42 Views:542

- Introduction

- How Integrated Circuits Work

- Structure and Components of an Integrated Circuit

- Types of Integrated Circuits

- Examples of Integrated Circuits

- Manufacturing Process of Integrated Circuits

- Advantages of Integrated Circuits

- Limitations of Integrated Circuits

- Applications of Integrated Circuits

- Conclusion

- Video: What Is An Integrated Circuit (IC)

Introduction

An integrated circuit (IC) or microchip is a type of miniature electronic circuit that features multiple connected components. This includes transistors, capacitors, and resistors. They are all fabricated onto a single semiconductor wafer. An integrated circuit is used for performing complex electronic functions, and it is what you are likely to find as a fundamental component in all modern electronics.

Integrated circuits have changed a lot since their introduction. They are currently more complex to handle different types of applications. The key advantages are that they are small in size, low cost, high performance, and still offer increased reliability than other circuits.

How Integrated Circuits Work

Integrated electronic circuits work differently depending on how they are configured and the signals they receive to process. For example, transistors can work as switches to control the current flow, or the IC can work as an amplifier to increase the signal strength.

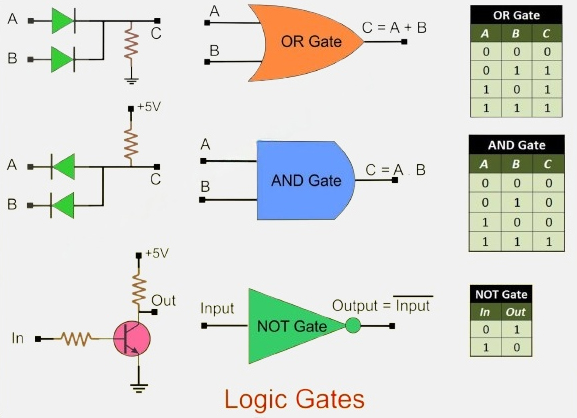

Digital ICs have logic gates for performing computations that depend on binary input. As for analog ICs, they use transistors, resistors, and capacitors to process continuous signals such as filtering radio frequencies or amplifying audio.

Structure and Components of an Integrated Circuit

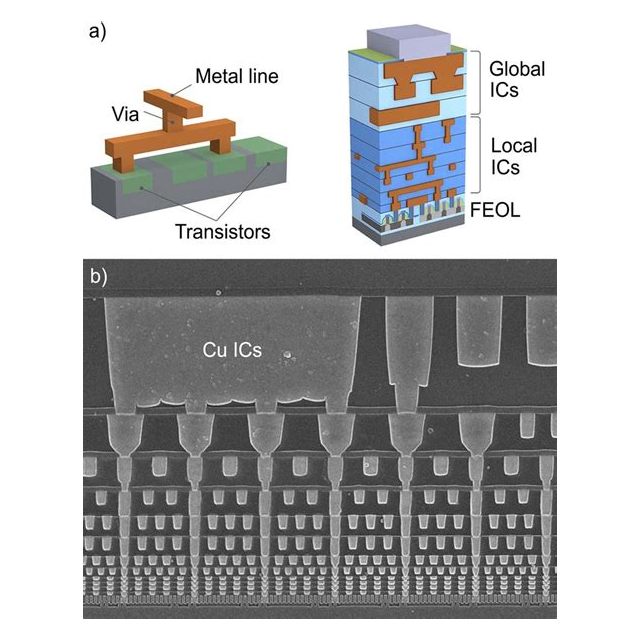

An integrated circuit chip features several components depending on how it works. For example, most of them have transistors, diodes, resistors, and capacitors. All these components are then fabricated onto a semiconductor wafer. They are also interconnected using methods such as photolithography, which ensures proper communication between different components.

Transistors in ICs are key for working as switches to control the flow of current in a circuit. Resistors, on the other hand, limit or regulate current flow.

Capacitors in integrated circuits store electrical energy and can be used for filtering or timing. Diodes allow the current to flow in a single direction only.

Interconnections are usually made using thin layers of metal. Copper or aluminum are suitable, as they are known for their impressive conductivity properties.

Types of Integrated Circuits

Now that we know what is an integrated circuit, let us look at the different types available and how they are used in electronics.

Digital Integrated Circuits

A digital IC is used for processing and manipulating digital signals, which represent data as discrete values. This means data is represented as 0s and 1s.

Common examples of such circuits include logic gates, flip-flops, counters, memory chips, microcontrollers, and others.

Digital ICs are mostly found in computers, digital cameras, smartphones, and other electronics that need to process discrete data.

They are commonly characterized by having high speed performance, low power consumption, and being easy to design if they are used for low-frequency applications.

Analog Integrated Circuits

An analog integrated circuit is used for processing continuous signals that vary over a range. Examples are current, voltage, and radio.

Some of the common uses include audio equipment, radio frequency (RF) circuits, sensor interfaces, and power management circuits.

They typically have fewer components than the digital ICs, but may also be complex to design, especially when dealing with high-frequency applications.

Mixed-Signal Integrated Circuits

For this kind of setup, you will have a combination of digital and analog circuits on a single chip. This enables the processing of the two types of signals, whether they are digital or analog.

Examples include digital to analog converters, analog to digital converters, and integrated circuits used in portable electronics, cars, and smartphones.

So long as an application requires the use of both analog and digital signals, you can use this type of IC. Since the IC can work for both digital and analog integration, expect it to have a complex design on a single chip.

Examples of Integrated Circuits

Examples of integrated circuit chips include microprocessors, memory chips, operational amplifiers, logic gates, and application-specific integrated circuits or ASICs.

Microprocessors are considered the brains of computers and other digital devices. They are responsible for executing instructions and performing calculations.

Memory chips are vital for data storage. It can be temporary for the case of RAM or permanent for the case of ROM. Using ROM allows the device to retain the data even when it is powered off.

Operational amplifiers or op-amp are analog ICs that amplify and process electrical signals. They are commonly used in audio amplifiers, control systems, and signal conditioning circuits.

Logic gates are digital ICs that perform basic logical operations, such as AND, NOT, OR, and others. They are key building blocks for more complex digital circuits and systems.

We also have the Application-Specific Integrated Circuits (ASICs) that are designed to achieve a specific application and not generic, compared to microprocessors and memory chips. This means they can be optimized for performance and power consumption depending on the application.

Manufacturing Process of Integrated Circuits

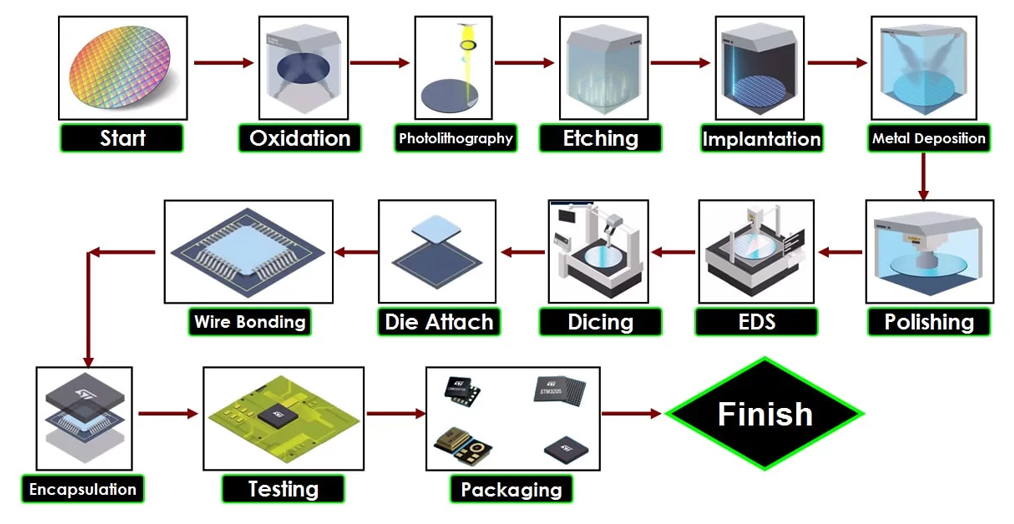

An IC manufacturing process can involve a lot of things. This includes the integrated circuit design until it is ready for distribution. Here is a typical manufacturing process for an IC.

1. Wafer Preparation

It is vital to have a good wafer that handles the final product correctly. So, the first process is to use pure silicon ingots that are sliced into thin wafers for mounting the other key components of an IC.

The wafer has to go through several cleaning and preparation steps to ensure there is a smooth and defect-free surface for subsequent processing.

2. Photolithography

This part of the manufacturing process involves transferring the circuit patterns to the wafer. A layer of photoresist ( a light sensitive material) is applied to the wafer and then it is exposed to a UV light through a mask to create the desired pattern.

3. Doping and Etching

Doping is when impurities are introduced into specific areas of the wafer to change its electrical properties. This is what leads to the creation of transistors and other key components.

As for etching, unwanted material is removed from the wafer using chemical and plasma etching. This further defines the circuit’s structure.

4. Metallization

Thin layers of metal such as aluminum are deposited onto the wafer to create the electrical connections between the various components of the integrated circuit. This is a crucial step to ensure there is proper conductivity and formation of interconnects on the IC.

5. Testing and Quality Control

Once metallization is done, the wafers are then tested to check for any defective circuits. Electrical testing is performed at various stages of the process to make sure that the circuit meets the required specifications.

6. Packaging and Distribution

Once the ICs are tested and they pass quality control tests, they are packaged and ready for shipping. The packaging is necessary to provide protection before they are connected to other components or circuits.

Advantages of Integrated Circuits

- The miniaturization of integrated circuit chips allows for the integration of numerous electronic components onto a single chip, drastically reducing the overall size of electronics.

- ICs also offer better reliability compared to other circuits, leading to fewer potential failure points. The manufacturing process also ensures better consistency and reliability, making them less prone to errors and defects.

- Since integrated circuits can be mass-produced in large quantities, they are less expensive than assembling individual components. This makes electronic devices generally more affordable to consumers.

- Improved performance is also possible because ICs can offer faster switching speeds and operate better at high frequencies. This is a good trait, especially for applications that require high-speed data processing.

- Reduced power consumption is now possible thanks to the compact size and efficient design of ICs. This leads to lower power consumption when compared to discrete circuits.

- Integrated circuits make higher functionality easier to achieve. This applies to basic logic operations, as well as to even more complex signal processing applications. It all depends on the various components integrated into the IC.

Limitations of Integrated Circuits

- Integrated circuits have power limitations as they cannot handle very high power levels.

- The speed of an IC can be constrained depending on the materials and the circuit design.

- ICs are also susceptible to temperature, which affects their performance at extreme temperatures.

Applications of Integrated Circuits

Some of the common applications of integrated circuits include:

- Computing is where they are used in microprocessors and CPUs. They are also used to make memory chips, graphic processing units, and chipsets.

- Integrated circuits are used in consumer electronics such as smartphones, game consoles, televisions, radios, and audio systems.

- Communication devices, including networking equipment and satellite communications, use ICs for signal transmission, reception, and processing.

- Fiber optics also use photonic integrated circuits, vital for their transmission of signals across the fiber optic cables.

- The automotive sector also has ICs in various parts, including the engine control unit, anti-lock braking system, infotainment, and many others. The ICs can do so much, including running the ECU that controls various aspects of the engine, or for ABS, which monitors the wheel speed and controls the braking force.

- The healthcare industry also uses ICs for medical imaging, patient monitoring systems, implants, hearing aids, and many others.

Conclusion

It is hard to get a modern electronic device without an integrated circuit. This is all thanks to how good the IC makes the devices to work. As much as they are built to deliver on complex tasks, ICs still remain more affordable. That is how electronics manufacturers are able to adopt the technology and pass down the savings to the consumer. Also, the power consumption is low, making modern electronics consume less power while still working better.

Video: What Is An Integrated Circuit (IC)

Please send RFQ , we will respond immediately.

Frequently Asked Questions

What materials are used to make integrated circuits?

Most ICs use silicon as their semiconductor material. Sometimes, gallium arsenide can also be used to make the base, mostly for specialized applications.

Where are ICs used today?

You can find ICs in almost all modern electronic devices. This includes smartphones, computers, medical devices, televisions, cars, and others

Can you repair integrated circuits?

Integrated circuits (ICs) are generally not repairable. The components are microscopic and inside a package, making it hard to repair individual parts. If an IC fails, it is best to replace it.