Role of a MAP Sensor in Fuel Efficiency & Engine Performance

Author:admin Date: 2025-10-17 10:19 Views:146

Introduction

The Manifold Absolute Pressure (MAP) sensor measures the pressure within the engine’s intake manifold. It converts it into an electrical signal, which is then sent to the Engine Control Unit (ECU) for interpretation. The ECU can now optimize the engine’s air-fuel mixture and other parameters that affect the engine’s performance. As you can see, the MAP sensor is crucial for achieving optimal fuel efficiency and engine performance.

Key Components of a MAP Sensor

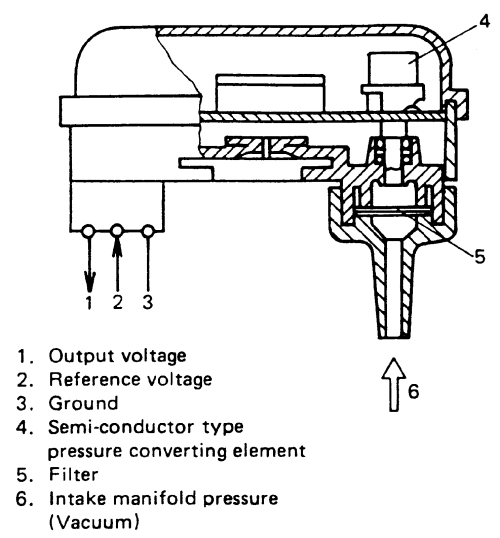

The key components of the MAP sensor include:

- Diaphragm: It is a flexible membrane designed to deform depending on the varying pressure in the intake manifold.

- Strain gauge or silicone chip: This component changes its electrical resistance depending on how the diaphragm bends.

- Wheatstone bridge circuit: It is a common electronic circuit used for converting resistance changes into voltage measurements.

- ECU: This is the engine’s computer that receives and interprets the signal from the MAP sensor.

How the MAP Sensor Works

Now that you know what is a MAP sensor and its components, let us see how it works.

There is a pressure to mechanical change as the air enters the intake manifold while the engine is running. The varying pressure exerts force on the diaphragm in the MAP sensor.

When the diaphragm deforms or bends in response to pressure, this movement is translated into a signal by a silicone chip or strain gauge. This is what changes the movement into an electrical resistance.

This electrical resistance is converted into an electrical signal, which can be in terms of frequency or voltage, and then sent to the engine’s ECU.

Once the ECU receives this information, it interprets the pressure value and determines what factors need to be adjusted to ensure the best engine performance and fuel efficiency. That is why the ECU will adjust the air-fuel ratio needed for the best combustion.

The data from the MAP sensor is also crucial for reduced emissions, in addition to proper engine performance and fuel efficiency.

Impact of the MAP Sensor on Fuel Efficiency

A MAP sensor’s role in fuel efficiency is based on how the ECU interprets and adjusts the air-fuel ratio. This shows the importance of having a sensor in great working condition. If the sensor is faulty, this is what you can expect:

- Decreased fuel economy as the ECU may inject too much or too little fuel-air mixture, leading to reduced engine performance

- Sometimes you may experience poor performance since the air-fuel ratio is disrupted. This results in poor engine performance, including rough idling, stalling, engine misfires, and hesitation.

- There can be increased emissions as well since fuel combustion is not done properly. This means you end up with increased harmful exhaust emissions such as hydrocarbons and carbon monoxide.

- A bad MAP may also cause extended cranking time or starting difficulties, especially in cold weather.

Effect of the MAP Sensor on Engine Performance

The MAP sensor can also affect engine performance in other ways, other than fuel efficiency. The engine uses its data to determine the engine load or the amount of pressure entering the engine. Based on such information, the ECU can calculate the right amount of fuel needed for optimal combustion. This is important to ensure a balanced air-fuel ratio.

The downside of having a faulty MAP sensor is that engine performance is reduced. This is what to expect:

- There is reduced engine power as the ECU incorrectly assumes there is less engine load and reduces fuel to the engine. As such, there is now insufficient fuel to meet the actual demand.

- Rough idling and stalling are also possible because of incorrect air-fuel mixtures. The result is less power and poor performance.

- In the case of a rich mixture or having too much fuel in the combustion chamber, it results in unburnt fuel, which is then expelled as black smoke.

- Difficulty starting or sometimes no-start is due to inaccurate reading. This could choke the engine by reducing the fuel and preventing combustion.

Common MAP Sensor Issues

There are signs of a bad MAP sensor that can tell you when it is time to have it checked. Below are the main faulty MAP sensor symptoms.

- A check engine light may appear and will trigger the codes P0105, P0106, P0107, or P0108. You will need a diagnostic kit to tell you more information about the code and how it can be resolved.

- Stalling is also common when the ECU continues to receive incorrect information. This prevents the engine from running properly at idle speed.

- A rough or surging idle is also common with a faulty MAP sensor. This is because the ECU is reading the wrong information from the sensor.

- Poor fuel economy is possible because the ECU may add too much fuel, resulting in an inefficient mixture or wasted fuel.

- Engine misfires also indicate an imbalanced air-fuel ratio, causing misfires in cylinders, which leads to the engine running unevenly.

Diagnosing and Fixing MAP Sensor Problems

Finding and fixing MAP sensor problems can be what you need to have the vehicle running right once again. Here are some tips to get you started.

- Use an OBD2 scanner

Connect an OBD2 scanner to the vehicle’s diagnostic port to retrieve any trouble codes that may be related to the MAP sensor. Some common trouble codes include P0107 and P0108. This allows you to further troubleshoot the MAP sensor and replace it where necessary.

- Inspect the sensor and wiring

A visual inspection is necessary to check if the MAP sensor is looking good or if there are issues. Inspect for physical damage, debris, or corrosion.

Also, check the wiring and connectors as well. Check for bends, loose terminals, or signs of rodent damage.

In case the MAP sensor of your vehicle uses a vacuum hose, check it for blockages, disconnections, or cracks.

- Test the MAP sensor with a multimeter

Use a multimeter to check if the sensor is working properly. Connect a probe of the multimeter to the signal wire and observe the voltage at different vacuum levels to check if the sensor is functioning correctly.

If you find that there are erratic or stuck readings on the multimeter, it means the sensor is faulty.

Potential Fixes

Try to clean the sensor and see how it responds. Sometimes, it just needs a cleaning to remove dirt and debris to keep it in good condition. Ensure you use the correct sensor cleaner.

In the case of a leaking vacuum line or broken wires, ensure they are repaired correctly. This will ensure good performance of the MAP sensor.

If the sensor itself is faulty, sometimes it is best to simply replace it. Make sure it matches the vehicle’s make and model.

Clear the codes and test again once you have completed the repairs. Give the car a test drive to see if there are changes to how it performs.

Conclusion

The MAP sensor is crucial to how the engine runs. That is why it should always be kept in great condition. The moment you start noticing issues such as rough idling, poor fuel economy, and reduced engine performance, it is best to consider testing your MAP sensor to ensure it is not the cause of the issues. If it is the one, we have shared steps you can take to remedy the situation and have the engine running right once again.

Video: MAP Sensor – Manifold Absolute Pressure

Please send RFQ , we will respond immediately.

Frequently Asked Questions

What is the difference between MAP sensor and MAF sensor?

A MAP sensor is vital for measuring the intake manifold pressure, while the MAF sensor is for measuring the actual mass of air entering the engine. The data from these two sensors is essential in how the ECU runs the engine. Therefore, they should always be in top condition to ensure the best performance of the engine.

Can a bad MAP sensor prevent the vehicle from starting?

In severe cases, YES. This is because the ECU may not be getting any information from the sensor. Therefore, you may end up with a difficult or unsuccessful start. In most cases, the engine runs poorly until the sensor is replaced.

Can cleaning a MAP sensor improve its performance?

Yes. If the sensor is dirty or clogged with carbon deposits, cleaning it can help improve its performance. Ensure you use an electronics-safe cleaner to restore accurate readings and further improve fuel efficiency.