Sensors 101: Everything You Need to Know Before Buying or Using One

Author:admin Date: 2025-12-16 10:05 Views:128

Introduction

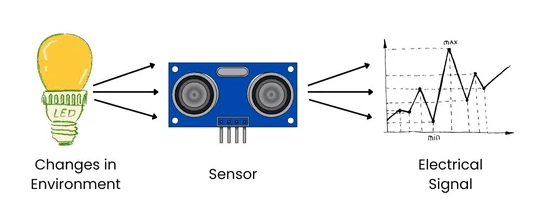

Sensors are devices that can detect and respond to physical, biological, and chemical inputs from an environment and convert them back into a measurable signal. You can look at sensors as the bridge between the physical world and digital systems. This leads to automation, monitoring, and intelligent decision-making in different fields and industries.

How Sensors Work

The functioning of a sensor is based on the principle of transduction, which is the conversion of one form of energy into another. Here is how the sensor works.

- Detection

The sensor has a sensitive element that physically interacts with the specific parameter it is designed to detect. Such include heat, light, or pressure.

- Transduction

This interaction causes a change in the material property of a sensor. It can be resistance, capacitance, or even the generation of a voltage. This change is then converted into an electrical signal.

- Signal Conditioning

The initial electrical signal is often weak and might be noisy. This means it needs to be processed. This stage typically involves processes such as amplification, filtering, and sometimes conversion into a digital format.

- Output

The processed signal is transmitted to a control system, data logging system, or display, where it can be easily interpreted. Once the data is received, it can be used to make decisions or trigger other actions.

What Can Sensors Detect?

Sensors can detect and measure a number of things, including physical, chemical, biological, and environmental parameters. Below are some of the things sensors can detect.

Physical

Sensors detect numerous physical properties and forces, including motion, position, and presence. Such include accelerometers, gyroscopes, and proximity sensors.

Force, pressure, and weight are also physical properties that can be measured. Other physical properties that can be measured include temperature, heat, light, sound, and vibration.

Chemical

You will come across chemical sensors that are designed to identify and quantify specific chemical substances. Some of the things measured include gases, pollutants, acidity, alkalinity, specific ions, and moisture.

Biological

Biosensors integrate biological elements such as enzymes or antibodies to detect and measure biological molecules or activity.

Good examples include glucose sensors for diabetic patients, which detect specific proteins or antibodies to help with disease detection.

It is the same for cellular responses in environmental monitoring and toxicity testing, which measure how living cells respond to toxins or pollutants.

Environment

Environmental sensors monitor various conditions that impact health or the surrounding ecosystem. Examples include weather conditions such as temperature, humidity, pressure, wind speeds, and direction.

The sensors can also measure air pollution levels, heavy metals, and contaminants in water and soil.

You may also encounter sensors that measure ionizing radiation levels in nuclear or medical environments.

Classification of Sensors

Sensors can be classified in many ways. We will consider classifications based on the technology they use, the signal they produce, and their operating characteristics.

Based on Technology

This classification looks into the physical or chemical principle the sensor uses for detecting a change.

Mechanical sensors are used to detect physical forces or displacement and convert them into measurable signals. They rely on the mechanical deformation of a material. Examples of such sensors include strain gauges, pressure sensors, and accelerometers.

Optical sensors are devices that detect light and other optical signals and convert them into electrical signals. Examples are photodiodes, phototransistors, LDRs, and color sensors.

Biosensors are specialized sensors that can integrate a biological recognition element, such as DNA, an antibody, or an enzyme, with a transducer to detect specific biological molecules or activity.

Based on Signal Type

This type of classification depends on the nature of the output electrical signal of the sensor. This includes analog and digital sensors.

The analog sensors provide a continuous output signal that is directly proportional to the physical quantity being measured. The output has infinite resolution within its range. Examples of such sensors include thermocouples, potentiometers, and standard strain gauges.

Digital sensors produce a discrete binary output, which can be pulses or serial data streams. A processor is built into the sensor to process the signal, leaving you with a signal that is more stable and immune to noise.

Based on Operation

This classification considers whether physical contact with the object being measured is required or whether an energy source is needed for operation.

Contact vs. Non-Contact Sensors

Contact sensors require direct physical contact with the subject they measure. We have examples such as thermocouples, touch sensors, and float level sensors.

As for non-contact sensors, they measure properties at a distance using waves, without physical contact. Examples include IR, proximity, and ultrasonic sensors.

Active vs. Passive Sensors

Active sensors need an external power source or signal to operate and produce an output signal. They emit a signal and detect how it is reflected and absorbed by the object. Examples include LVDT sensors, radar, and proximity sensors.

Passive sensors do not need an external power source. They can easily detect and respond to naturally occurring energy or signals emitted or reflected by the target object or environment.

Sensor Technologies Explained

There are several key technologies and operational principles in sensors today. Understanding them helps you find the right sensors. Here are some of them:

MEMS Technology in Modern Sensors

Micro-Electro-Mechanical Systems (MEMS) technology is involved in the miniaturization of mechanical elements such as mirrors, beams, or gears and electronics onto a single chip using microfabrication techniques.

The advantage of this technology is that the sensors are tiny and lightweight. They also consume little power and can be mass-produced at low cost.

Piezoelectric Sensing

In this case, certain materials, such as ceramics and quartz, generate an electric charge in response to mechanical stress or pressure. They are generally highly responsive, robust, and capable of measuring rapid changes in force or pressure.

Applications include microphones, impact sensors, and pressure sensors.

Capacitive vs. Inductive Principles

These are two common non-contact sensing principles. They are primarily used for proximity and position detection.

Capacitive sensors measure changes in capacitance when an object enters an electric field. Applications for this case include touchscreens, proximity detection, and liquid level sensing.

As for inductive sensors, they measure changes in inductance caused by an object entering a magnetic field. Examples include detecting metal parts on assembly lines and automotive wheel-speed sensing.

Infrared Sensing: Active vs. Passive

Infrared or IR sensors detect infrared radiation. They can either be active or passive.

The active IR sensors contain both a transmitter and a receiver. The transmitter sends an IR signal, and the receiver quickly detects whether the signal is reflected or interrupted by an object.

Passive IR only has a receiver. They detect naturally occurring infrared radiation emitted by humans or objects. Examples of such include motion detectors for automatic lighting or security systems.

Sensor Applications Across Industries

Sensors are quite important in many industries. Below, we look at the most common applications of sensors in different fields.

- Consumer and Smart Devices

Sensors are fundamental to enhancing the experience and functionality of everyday devices such as smartphones, wearables, and IoT devices.

Smartphones come with many sensors, including accelerometers, gyroscopes, magnetometers, light sensors, and proximity sensors.

- Industrial and Automation

In industrial settings, sensors are used to ensure efficiency, safety, and improve manufacturing practices.

Industrial IoT sensors are used to enable predictive maintenance, monitor machine vibrations and temperatures, and anticipate failures before they occur to minimize downtime.

We also have them in robotics and automation sensors. Robots use proximity, force, and vision sensors for navigating their environment. This ensures they interact safely with objects and perform precise tasks as programmed.

- Automotive and Transport

The automotive industry relies on a complex network of sensors to improve safety, performance, and enable the transition to autonomous vehicles. We have examples such as ADAS systems that use LiDAR, radar, and ultrasonic sensors for features like adaptive cruise control, collision avoidance, and blind-spot detection.

TPMS, Engine sensors, and Airbag sensors are also present in modern vehicles to ensure vehicle safety. Still, they ensure the engine performs optimally to avoid emission issues.

- Medical and Healthcare

Sensors have also revolutionized medical diagnostics. You can be sure to get better patient care with more sensors now in place.

Diagnostic sensors are now used in medical imaging, such as MRI and CT scans, to enable rapid patient testing. You also get wearable health sensors that monitor vital signs, track movement disorders, and facilitate remote patient monitoring for those with chronic conditions.

- Environmental and Infrastructure

Sensors are also used to provide critical data to help you understand and manage the environment and physical infrastructure. You have options such as weather-monitoring sensors, pollution and air-quality sensors, and smart-city sensors.

The sensors in smart cities are integrated in various applications such as managing traffic flow, optimizing waste collection routes, and monitoring the structural health of buildings and bridges.

- Agriculture and Food Industry

The agricultural industry also uses sensors to optimize crop yields and minimize resource use. The food industry, on the other hand, uses these sensors for safety and quality control.

Right now, there are a lot of smart farming practices, such as using drones and field sensors to know when to irrigate, fertilize, and do pest control.

You also get food safety sensors that can be used to detect pathogens, contaminants, and spoilage.

Sensor Performance & Selection Criteria

Selecting the appropriate sensor can determine how well it will work for your application. A couple of factors, such as sensor performance, will determine your choice. Here is what to do.

Accuracy, Precision, and Resolution

These three terms describe how well a sensor measures the value of an object relative to the truth.

Accuracy is how close the sensor’s measurement is to the true or actual value of the physical quantity being measured. Having highly accurate sensors means you get readings that are correct on average.

Precision is the ability of a sensor to produce the same reading consistently when measuring the same static input value under the same conditions. A precise sensor may not always be accurate, but its reading will be consistent.

Resolution is the smallest change in the physical input that the sensor can reliably detect and measure. A high-resolution sensor can detect minute changes in temperature, pressure, and more.

Sensitivity, Range, and Response Time

These metrics define the sensor’s operational limits and speed.

Sensitivity is the ratio of the change in the sensor’s output to the change in the physical input quantity. Having a high-sensitivity sensor produces a large output change for a small input change.

Range or span is the minimum and maximum values of a physical quantity that the sensor can measure effectively.

Response time is the time taken for the sensor’s output to reach a stable value after a sudden change in the input quantity.

Stability and Drift

These factors relate to the sensor’s reliability over time and the varying conditions.

Stability is the ability of the sensor to maintain its performance over an extended period. A stable sensor provides consistent accuracy over its operational life.

Drift is the gradual change in a sensor’s output reading over time when the actual value remains constant. Zero-point or span drift is a key consideration for those with long-term monitoring applications.

Environmental and Durability Considerations

The sensor is likely to be exposed to environmental conditions that can affect its durability and performance. So, protection ratings are critical.

Look at the operating temperature range and humidity performance. Sensors must be built to function reliably within the ambient temperature and humidity extremes of the application environment.

IP rating indicates a sensor’s resistance to water and dust. This is essential for outdoor or industrial use.

Vibration and shock resistance are also important especially if the sensors will be used in automotive, mobile, or industrial applications. The sensors must be able to withstand mechanical stresses without failure.

Conclusion

Sensors serve as a critical interface between the physical environment and the digital world. Sensors use technologies such as MEMS, LiDAR, and others to detect phenomena including motion, temperature, chemical composition, and light. It then converts the inputs into actionable signals. Effective selection and deployment of sensors across various industries requires a careful balance of performance and practical considerations such as power, durability, and interfacing standards.

Please send RFQ , we will respond immediately.

Frequently Asked Questions

What is the difference between analog and digital sensors?

Analog sensors produce continuous signals that vary over a range, while digital sensors produce discrete signals by using communication protocols such as I2C, SPI, and UART.

How can you choose the right sensor for my project?

You may want to consider what quantity you need to measure, power consumption, budget, lifespan, and output type.

What is the role of sensors in IoT?

Sensors collect real-time data that the IoT devices need to automate processes, perform analytics, send alerts, and make intelligent decisions. They are the foundation of many smart homes, connected cities, and smart factories.