Expert Guide to Toggle Switches: Specs, Types, and Installation Tips

Author:admin Date: 2025-11-08 04:10 Views:139

- Introduction

- Toggle Switches Internal Mechanism & Construction

- How a Toggle Switch Works

- Electrical Ratings & Technical Specifications of Toggle Switches

- Types of Toggle Switches Common

- Applications of Toggle Switches

- How to Choose the Right Toggle Switch

- Wiring & Installation of Toggle Switches

- Testing, Maintenance & Troubleshooting of Toggle Switches

- Conclusion

Introduction

A toggle switch is a mechanical electrical switch that has a lever or handle to open or close a circuit. Users have to manually move the lever to one, two or more positions. Such switches provide simple and reliable methods for controlling the flow of electricity. Expect it to be a common switch for basic on and off functions.

Toggle Switches Internal Mechanism & Construction

The internal mechanism of the toggle switches helps us understand how they work. The core principle is that when you physically move the conductive contacts, they can make or break the circuit.

The main components include:

- Lever or actuator: This is an external manually operated handle. It is mostly made of metal or a resin for durability. Its interface is generally user-friendly, so that you can operate it with ease.

- Moving armature: This is connected to the lever internally, and it features a conductive metal part. It moves when the lever is toggled. Its movement is what makes or breaks the connections with the fixed contacts.

- Fixed contacts: These are stationary metal terminals in the switch’s housing. They are mostly made of silver or copper alloy to ensure good conductivity and corrosion resistance. Whenever the moving armature touches them, a circuit is completed.

- Springs and detents: Springs provide the necessary mechanical force for the switching action. For example, the maintained switches have springs that push the lever firmly into the on or off detent. As for the momentary switches, the spring returns the lever to the normal position if released.

- Plunger: This is often a resin component attached to the bottom of the lever. Its job is to guide the moving armature and restrict the lever’s range of motion.

- Housing: This is the protective casing largely made of durable plastic or metal. It encloses all the mentioned internal parts above, providing structural support and insulation between components.

- Insulating materials and O-rings: The insulating materials are strategically placed to prevent electrical shorts. O-rings and other seals protect the internal mechanisms from dust, moisture, and other contaminants.

How a Toggle Switch Works

How a toggle switch works is quite simple, and it does not involve much. Here is what to expect:

- Whenever the user moves the external lever, the action moves the internal plunger and the moving armature.

- The spring mechanism controls the force and speed of contact engagement or disengagement. This ensures a quick and reliable connection. The rapid movement is important to minimize arcing at the contact points, which would otherwise lead to premature wear.

- Once in the ON position, the moving armature bridges the gap between the fixed contacts and the external circuit. This allows current to flow from the terminal to the other terminal.

- In the OFF position, the armature moves away from the fixed contacts, opening the circuit. This interrupts the flow of electricity.

Electrical Ratings & Technical Specifications of Toggle Switches

Whether it is a 2-way or 3-way toggle switch, each will come with key electrical ratings and technical specifications to determine how best they can be used.

Electrical ratings

The primary ratings of toggle switches include voltage, current, and power ratings.

The voltage rating in volts specifies the maximum voltage the switch can handle safely. You should never exceed the rated voltage, as it can cause arcing across open contacts.

The current rating measured in amperes indicates the maximum amount of continuous current the switch can carry safely without overheating. The switch can fail if used with a circuit carrying a current higher than its rated current.

Power rating is measured in watts and indicates the maximum power the switch can handle. This is important for all high-powered applications.

Load type is another important consideration. Expect the toggle switches to work with different types of electrical loads. For example, you can have various types of loads, such as resistive, inductive, lamp load, or motor load. The lamp and inductive loads tend to have a higher inrush current, which the toggle switch should be able to withstand without welding shut.

For technical specifications, consult the switch’s data sheet. Such features include:

- Contact resistance

- Insulation resistance

- Dielectric strength

- Electrical life cycle

- Mechanical life cycle

- Operating temperature

- Certifications

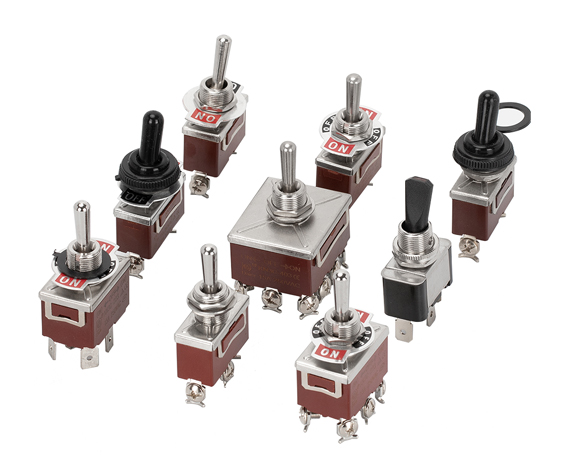

Types of Toggle Switches Common

Toggle switches are largely categorized based on their electrical configurations and their operational characteristics.

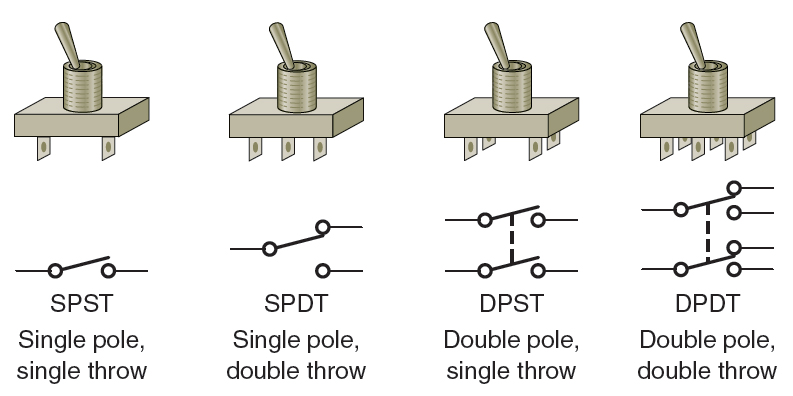

Types Based on Electrical Configuration (Poles and Throws)

The term pole means the number of circuits controlled, and throw is the number of positions each circuit can connect to. This can define the internal wiring and function of the switch.

Such include:

- Single-Pole Single-Throw (SPST)

These are the most basic configurations of the toggle light switch or any other type. Its wiring controls a single circuit and has only two states: ON and OFF.

Common applications include household light switches, lamps, and simple fan controls.

- Single-Pole Double-Throw (SPDT)

This toggle switch wiring controls one circuit, but can direct current to one or two different outputs. So, it can work as an ON-ON switch or ON-OFF-ON switch having a center-off position.

These toggle switches are largely used for three-way light circuits. That is how you will come across 3-way toggle switches. Also, they can be used for switching between high and low beams in a vehicle or choosing between two power sources.

- Double-Pole Single-Throw (DPST)

Acts like having two synchronized SPST switches, controlling two independent circuits simultaneously with a single movement. It has two positions: ON/OFF.

It is a common connection in industrial or commercial settings where it is possible to disconnect both the live and neutral wires for safety. For example, in electric water heaters or ovens.

- Double-Pole Double-Throw (DPDT)

This is the most versatile type of toggle switch wiring. In this case, it functions like two synchronized SPDT switches. It can be used to switch two separate circuits between two different outputs.

It is largely used for reversing the direction of a DC motor or in a complex circuit involving machinery.

Types Based on Operational Action

Toggle switches are also classified based on how the lever behaves after it is moved. The main options include maintained contact or latching and momentary contact.

In maintained contact, the toggle switch remains in the position it was moved to until the user moves it back manually. The common applications include light switches and industrial control panels.

In momentary contact, the switch only remains in the actuated position as long as the user holds the lever in that position. Once the user releases the lever, it returns to the original position. Examples of such toggle switches include doorbell buttons, start/stop controls on test equipment, and more.

Applications of Toggle Switches

The toggle switches can be used in a wide range of applications, including:

- Household and consumer electronics for lighting systems, appliances, home automation, and audio/visual equipment.

- Automotive and transportation systems, including vehicle controls, boats, and auxiliary systems such as recreational vehicles.

- Industrial and commercial applications for machinery control panels, safety protocols, and power tools.

- Aerospace and military spaces, including cockpit controls and communication equipment.

- Medical devices such as wheelchairs, diagnostic equipment, and hospital beds

How to Choose the Right Toggle Switch

Whether you want a simple or 3-position toggle switch, it is important always to pick the right switch. There are several things to keep in mind if you want to get the right toggle switch. Here are the various considerations.

- Electrical requirements

This is definitely the most important consideration, as it determines if the toggle switch will work great for your application.

Look at the voltage rating, current rating, and power ratings under this requirement to ensure that your choice is safe to work with in a certain circuit.

Also, look at the safety certifications such as UL, CSA, and others to ensure the switch can meet established safety and performance standards.

- Operational function

Consider how the switch works to determine whether it fits your system. Examples include poles and throws to get various types of switches such as SPST, SPDT, DPST, and DPDT.

The action type is also important to consider. The main options include maintained or latching, and momentary. Understanding how each works should make it easier to choose the right one.

- Environmental considerations

The operating environment often determines the level of protection for the internal components of the switch.

Look at the IP Rating as it indicates the switch’s resistance to dust and water. Having a higher rating, such as IP67, is vital for outdoor, marine, and dusty industrial applications.

Temperature and vibrations are also important to consider, as you need a switch that can handle the operation’s temperature range. Also, vibrations can damage a switch; make sure it can handle them as well.

- Mechanical and physical factors

The physical aspects of a toggle dimmer switch or any other type need to align with your design and ease of use.

Look at the mounting style. For example, you get to choose between the panel mount, PCB mount, or surface mount.

You can also choose the actuator (level) style, including the size and shape. Common examples include standard, bat handle, ball end, and more.

The terminal type can also be a factor. The common options include screw terminals, quick-connect tabs, and solder terminals. Make sure it matches your wiring method.

Wiring & Installation of Toggle Switches

Always make sure that you turn off the power supply to the circuit before you start working on the switch. Follow these steps:

- Gather the tools you need for installing the toggle switch. Some of the tools include strippers/cutters, a drill and bit for mounting on panels, a screwdriver, and safety gear.

- Prepare the mounting surface by drilling a hole of the correct diameter for the switch to fit correctly.

- Mount the switch into the hole. Secure it using the mounting nut and washer. Ensure it is flush and stable.

- Prepare the wires by stripping approximately ½ inch of insulation from the ends of the wire to show the conductor.

- Identify the terminals for proper wiring. Examples include Common (COM), NO, NC, or others, which can be numbered 1, 2, 3

- Connect the wires according to your application. Just make sure the wires are secretly held in the switch’s terminals.

- Proceed to secure and test the switch to see if it works properly. Make adjustments where necessary.

Testing, Maintenance & Troubleshooting of Toggle Switches

Testing an ON-OFF toggle switch can be done using a multimeter. It helps a lot in determining whether the switch is in good working order. Here is how to test with a multimeter.

- Disconnect all power to the circuit is off

- Disconnect the switch from the circuit

- Set the multimeter to the continuity setting or resistance setting

- Test the toggle switch in the OFF position. Place the multimeter probes on the SPST switch. Since it is in the OFF position, the multimeter should read an open circuit. There will be no beep, OL, or 1 for resistance.

- Test the toggle switch in the ON position. In this case, the meter should now show there is continuity. Expect a solid beep, or the reading in terms of resistance will be close to 0 ohms.

- If you have to test the multi-throw switches, follow the same process, but you have to test for continuity between the common terminal and each of the other terminals in different switch positions.

In the case of maintenance and troubleshooting, here is what you can do.

- If the switch feels loose or won’t stay in place, it means the internal detent is worn or the spring mechanism is broken. In this case, simply replace the switch.

- The switch feels sticky or stiff. This means there is dirt, debris, or moisture in the housing. Cleaning the exterior can help maintain the functionality of the switch. However, if the internal mechanism is damaged, then replace it.

- The switch is hot to the touch. This is caused by overcurrent conduction, loose connections, or an undersized switch. Turn off the power and check the circuit’s current and wiring connections. Replace the switch if it is incorrectly sized.

- The switch sparks or makes a loud arcing sound. It shows that a high-voltage or high-current load is on the switch. Turn off the power immediately, then check all connections and ratings, making sure you are using the correct switch for the job.

Conclusion

Toggle switches are important in electronics. We have seen how they can be key for handling various applications we use in our daily lives. You simply have to flip a switch, and you achieve a certain functionality. Always get the best toggle switch from top brands to ensure the performance is guaranteed.

Please send RFQ , we will respond immediately.

Frequently Asked Questions

Can you use toggle switches for high-current applications?

Yes, but only if the switches are rated for high current. The heavy-duty industrial toggle switches are designed to handle 20A or more. However, the small miniature switches are best for low-current circuits.

Are toggle switches safe for outdoor or wet environments?

Yes, but make sure they are waterproof or IP-rated for applications such as boats, outdoors, or in high-moisture areas. The regular toggle switches can easily corrode or short-circuit if exposed to water.

Should you install a toggle switch yourself?

It is possible to install the toggle switch as a DIY project. Make sure you have basic wiring knowledge to determine the best way to wire the switch. If you are working with high voltage, we recommend getting a professional to work on the project.