What Are Power Connectors? Types, Applications

Author:admin Date: 2025-10-17 08:11 Views:124

Introduction

A power connector is a type of electromechanical device used for transmitting electricity from a power source to an electronic device safely. It is a vital link for completing a circuit. The power connector largely depends on the voltage, current, capacity, and the application.

Expect to come across multiple options for power connectors in this guide. We also mention the applications, how it works, and much more. Keep reading.

How Power Connectors Work

A power connecter comes with several components that make it work as expected. The male component (plug) and the female component (socket) fit together to complete the circuit.

Once the circuit is complete, electricity flows from the power source to the device and back. It is important to take note of the polarity to ensure proper connection and a safe operation.

Many connectors come with specific shapes, sizes, or keys. This ensures that you can always plug in correctly.

Key Components of a Power Connector

Include an image showing parts of a power connector

The core components of the nest power connector include:

- Contacts: These are conductive parts of the connector. They are mostly a male pin and a female socket. They are supposed to make contact to complete the circuit. These are made of copper or brass and might be plated to avoid corrosion and conductivity.

- Insulator: The insulator is the non-conductive material that holds the contacts in place. It also ensures there is proper spacing and further prevents short circuits.

- Shell: This is the external housing of the connector that provides mechanical protection. It still aligns the plug and socket during the mating process. It can also secure the connector to the device.

- Conductors: These are the wires that carry the electrical current from a power source to contacts of the power connector.

Sometimes you may come across secondary components which are an addon for a power connector to work. Examples include:

- Locking mechanisms to make sure there is no accidental disconnection. This is something more power connector manufacturers are implementing to ensure no disconnection even in high-vibration environments.

- Accessories are the additional parts that can aid in installation and functionality of the connector. Examples of accessories include guiding pins, gaskets for sealing, cable clamps, or screws and nuts.

- Shielding is also possible with some connectors and cables. A shielding layer is added to the connector and cables to protect against electromagnetic interference.

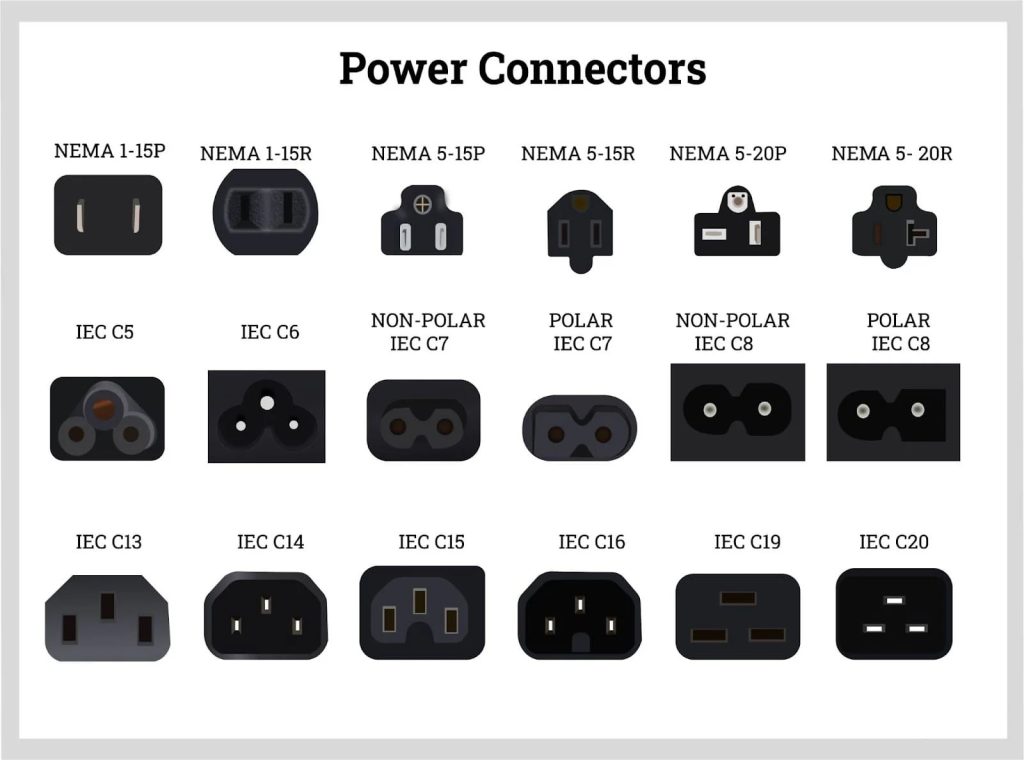

Main Types of Power Connectors

Whether you want the EU power connector or Anderson power connectors, there are several types to choose from. Below are the main options you will find in the market.

- AC Power Connectors

The alternating current (AC) connectors are for connecting to the mains electricity in commercial, industrial, and residential settings.

The common types include:

- NEMA: This is used for the North America standard for wall outlets and plugs

- IEC: This standard is common the appliance side of the power cord. Eamples include computers and TVs.

- CEE: These are industrial grade connectors mostly for high power and rugged applications.

Expect to find the AC connectors being used with a wide range of devices ranging from household appliances to industrial machinery.

- DC Power Connectors

Direct current (DC) connectors work with DC power supply. It is used to connect to a power adapter or battery to a device. You may come across multiple options for this type of power connectors. Just make sure it is compatible with the device.

Examples of DC power connectors include:

- Barrel connectors

- Coaxial connectors

- Anderson power connectors

Always look at the size of the pins or diameter to ensure it works with the device’s port. Also, the polarity is important to consider. This is to ensure that the positive and negative terminals are correctly connected to avoid potential damage to a device.

- Circular vs. Rectangular Connectors

Circular connectors are loved for being able to offer high-density pin configurations, secure locking mechanisms, and good mechanical strength. However, they can be bulkier than the rectangular power connectors and more expensive.

Rectangular connectors are generally easier to align and will be more compact for various applications such as internal computer connections. Generally has fewer locking options and will not be as robust for heavy-duty use compared to the circular power connectors.

- Specialized Power Connectors

Magnetic connectors are some of the best specialized power connectors. This is because they help with aligning and connecting to the device. A good example is the Apple’s MagSafe which is not easy to disconnect accidentally.

USB power delivery via USB-C. This is a new versatile standard that many modern devices have embraced. So, you can now deliver high power to devices via USB mostly for charging laptops and other related devices.

XT series connectors are also a specialized option for powering drone and RCs. They are mainly designed for high-current applications. Examples of such connectors are XT30, XT60, and XT90. The numbers indicate the current rating.

The aviation and waterproof connectors are the best for harsh environments. They come with features such as secure locking mechanisms and seals to prevent dust, water, and other contaminants from getting into the connector.

Applications of Power Connectors

Power supply connectors can be found across different industries. Below we look at the various industries with power connectors.

- Industrial automation and robotics: Here, they have high current capacity and are build to resist vibration. This is to ensure they offer reliable connections in demanding environments.

- Automotive and electric vehicles: These are used for high-voltage systems since they are good in terms of durability and water resistance. The aim is to ensure they can handle high power and still offer safety requirements for electric vehicle charging and the internal systems as well.

- Renewable energy systems: These are mostly built to be waterproof and designed for handling high-power applications. The main purpose is to transmit power in outdoor environments. They are good for managing high voltages and currents.

- Medical equipment: These power connectors are best suited for the medical environment. They are safety-certified and sterilization-resistant power connectors that may have to be cleaned and sterilized more often.

- Consumer electronics and computing: These are the common types of power connectors available in the market. Examples include USB-C, DC jacks, and others. They are used for providing power to a wide range of personal devices.

- Aerospace and defense: These power connectors are built to be lightweight, rugged, and EMI-shielded. This is to ensure they supply reliable power in the most extreme conditions while also keeping the weight low. Also, electromagnetic interference is blocked for reliability.

Power Connector Standards and Ratings

The connector standards are important for guiding how the power connectors are built and the ratings specify how much voltage and current the connector can handle.

The common standards include:

- NEMA: They are used in North America for their AC mains. They have a rating of 15 to 60A for current and 125 to 600V for the voltage.

- IEC: These are international standards for connects set by the International Electrotechnical Commission. Examples include:

- C13/C14

- C5/C6

- C7/C8

- C15/C16

- C19/C20

- DC power connectors: These types of connectors are not standardized. Most devices will come with barrel type of connectors.

How to Choose Power Connectors

There are a couple of things you must consider for the choice of power connectors. Such include electrical, mechanical, environmentals, and materials and safety.

Electrical Considerations

The connector must be rated depending on the specific voltage and current loads. Still, contact resistance is an important consideration. Low contact resistance is important to minimize power loss and heat. Contact plating may be necessary to ensure better performance.

Multiple pins are vital for high-current paths. Make sure to also optimize for minimal voltage drop across the connection.

Appropriate spacing, grounding, and spacing are vital for signal integrity even for power connectors.

Mechanical Considerations

The physical dimensions such as the size and footprint must fit in the available space. This is why you can come across the miniaturized connectors that can fit in the allocated space. Or, you may have to arrange multiple connectors in a way they fit.

Another consideration is the mating cycle. You need power connectors with high mating cycle rating if you expect to do frequent connections and disconnections.

The durability of the RV power connector or any other type is important. This is to ensure that it can withdrstand the intended environment. For example if they will be used in industrial setup.

Make sure to select the appropriate termination method such as surface mount or through-hole. It all depends on the intended application.

Environmental Considerations

The operating conditions can impact how the power connector can work in temperature extremes, humidity, and potential exposure to chemicals and contaminants.

The design should also consider environments with vibrations and shocks. This is because such conditions can cause component wear or disconnect accidentally. Having latching mechanisms and use of robust retention features works quite well.

Sealing is also important if the application requires it. Ensure that the connector is waterproof in such an application to prevent water or debris from getting in.

Materials and Safety

The materials selection is vital for the housing and contacts to ensure it withstands the operating temperature or any other conditions where the connector is used.

In the case of high current applications, it is expected that the operation can generate heat. So, it is important to have adequate cooling and ventilation.

Power Connector Maintenance and Troubleshooting

Maintenance

- Disconnect all the power sources before you can start cleaning or working on connectors

- Perform visual inspection looking for signs of physical damage including cuts, cracks, or abrasions.

- Clean the contacts using a soft brush and contact cleaner for removing dirt and oxidation.

- Allow the connectors to completely dry after cleaning before re-inserting the connector back into a socket.

Troubleshooting

- Check if the physical connection is secure on both ends. A loose fit can easily lead to power problems.

- Gently wiggle the connector while the device is on. If the power keeps cutting in and out, it shows there is a loose connection or there is an internal fault in the connector.

- Test the power connecter with a multimeter. It will help with checking if the correct voltage is being transmitted or there is continuity.

- Check for the pin fitment as well. Sometimes a broken pin in the power connector can lead to connectivity issues. For such a case, replacing the power connector is necessary.

- Inspect the wires ensuring they are securely crimped to their terminals and there are no loose wires.

Conclusion

Power connectors are essential to ensure that devices can connect to the power supply securely and safely. There are multiple types of power connectors you can use depending on the application. It is important to understand what you need to pick the right connector. Also, make sure you choose a top brand as well since they can assure you of the best quality for power connectors. Do not forget regular maintenance to keep the power connectors in great condition.

Video: Power Connectors – Overview

Please send RFQ , we will respond immediately.

Frequently Asked Questions

Can you use AC and DC connectors interchangeably?

No. These two are designed for different applications. It is vital that you always choose the right connector for an application. For example, the AC connector is designed for alternating current and will have grounding and polarization features. As for DC connectors, they are built for direct current and need the correct polarity alignment.

What can happen when you use the wrong power connector?

Using the wrong connector may cause voltage drops, overheating, or complete equipment failure. The mismatched connectors lead to improper contact which now results in the stated problems above.

How often should you replace a power connector?

It all depends on the condition of the power connector. Make sure that you keep inspecting the power connectors more often to ensure that you can catch a problem before it becomes impossible to use the device. Look for signs of wear, burn marks, corrosions, loose pins, and cracked insulation.