What Is an Armature in Electronics? The Key to Electromechanical Motion

Author:admin Date: 2025-07-29 07:33 Views:447

Introduction

The armature plays a crucial role in the operation of both electric motors and generators. Found on the rotating part of the machine, it contains coils that either deliver current (in motors) or generate voltage (in generators).

Its primary function is to interact with the magnetic field, enabling energy conversion, producing mechanical force in motors and electrical output in generators.

An armature can be found both in AC and DC machines doing the same job. In the AC machines, it conducts alternating current directly, while in DC machines, it does so through a commutator.

We will take a better look at the types of armatures, their roles, uses, and much more. This is to help you learn more about such units in addition to the armature definition.

Armatures’ Importance in Electromechanical Systems

An armature wiring is important in electromechanical systems in the following ways:

Current Conduction

Copper is a popular material for making the windings. This is because copper is good at conducting electric current.

Torque Production

The armature in motors generates torque as it spins. This is possible because electromagnetic induction leads to torque in this setup.

EMF Generation

When the coil inside a generator spins within a magnetic field, it interacts with armature windings to generate an electric current also known as EMF generation. This interaction is the fundamental mechanism that transforms mechanical energy into electrical power.

Conversion

The armature of an electric motor converts electrical energy into mechanical energy. The same converts mechanical energy into electrical energy in the case of generators.

Components of an Armature

The components of motor or generator armature are key in ensuring it can deliver on performance. The main parts include a core, winding, shaft, and commutator.

Core

The armature core is made of laminated silicon steel. These thin metal plates work to reduce energy losses caused by eddy currents, which are small circulating currents induced in the core by the rotating magnetic field.

The core is also vital for providing a structure for the armature windings and can help concentrate the armature’s magnetic flux.

Winding

The armature winding features coils of insulated wire wound around the core. Whenever current flows through the windings, a magnetic field is generated. Torque in motors or voltage in generators is induced whenever this magnetic field interacts with the external magnetic field.

Commutator

This is a segmented ring of conducting material, often copper, connected to the armature winding. It works as a mechanical switch, reversing the current direction in the windings as the armature rotates. The result is continuous and efficient motor rotation or voltage generation in generators.

Shafts

A shaft is a rigid rod that supports the commutator and armature core. It also transmits the rotational motion from the armature to a load connected to a motor.

Types of Armatures

Now that we understand the armature definition, let us look at the types to know which type you should get if you ever need one. There are two main types which include lap winding and wave winding armatures.

Lap Winding

In lap winding configurations, each coil is connected to the commutator segment directly next to it. A key feature of this type of winding is that the number of parallel current paths corresponds to the number of magnetic poles in the motor or generator.

This design is especially suitable for systems that require high current at lower voltages. There are different forms of lap winding—such as simplex, duplex, and triplex—which vary in how many parallel paths they provide, depending on the complexity of the application.

Wave Winding

In this case, the coil ends are connected to commutator segments set at two pitches apart. The wave endings generally have only two parallel paths, irrespective of the pole numbers.

The design of such windings makes them ideal for high voltage and low current applications. The wave windings setup can also be duplex, simplex, or triplex, but the number of parallel paths will remain as two.

Materials Used in Armature Construction

Whether it is a starter armature or any other type, the materials used in its construction can determine how well it works. These materials include:

- Copper: This material is known for its high electrical conductivity. You can expect to find it being used for windings in different applications.

- Steel: This is used for providing the structural strength needed to make the armature stable. As such, it can withstand mechanical stresses and torque with ease.

- Aluminum: This is a lightweight alternative to steel. You can expect it to be a useful alternative in more intricate armatures.

- Laminated iron or steel: This material is commonly used as the core of many electrical machines. The design allows for the reduction of eddy current losses and further improves the overall magnetic field efficiency.

- Insulation: Materials such as enamel or varnish are essential for insulating the armature windings. This prevents cases of short circuits and ensures there is proper current flow.

- Commutator: This is a feature in DC machines. It is made of copper segments that transfer the current between the rotating armature and the external circuit.

Applications of Armatures

Armatures are important components in electric motors and generators. In electric motors, armatures are important for creating the torque or driving force for the motor’s shaft. Expect to find them in different applications, including electric vehicles and even household appliances.

As for generators, the armatures are important for converting the mechanical energy into electrical energy. They can be used in wind turbines, power plants, and other energy generation systems.

You can also find them in other applications such as automotive, power tools, medical devices, and many industrial applications. The chances are they will either be part of a generator or a motor serving different purposes.

Armature Resistance and Losses

The armature resistance is the resistance of the armature windings. This resistance is often small, but can often lead to power losses in the form of heat. This is also known as armature copper losses.

The armature resistance is not always bad. For example, it is used to help start DC motors. This is because a high initial current in DC motors may cause damage if it is not limited.

The copper losses for an armature in motors vary and may increase with the square of the armature current.

Other than the armature winding resistance, there is also the brush contact resistance which also leads to copper losses. The brush contact resistance is often included in the calculation of copper losses to understand the performance of the system.

Besides the copper losses, other notable losses include iron and mechanical losses. It is best to take them into account when designing motors and generators so that you can improve where necessary.

You might be wondering, how does armature resistance affect performance?

In DC motors, the armature resistance is important for starting them. A series resistance can be added to the armature circuit to help limit the initial current and prevent damage to the motor.

The resistance added to the armature winding can also be used for speed control. However, this method may reduce overall efficiency and lead to additional losses.

The armature copper losses will directly impact the machine’s efficiency. It is therefore important to reduce the losses so that the overall efficiency can improve.

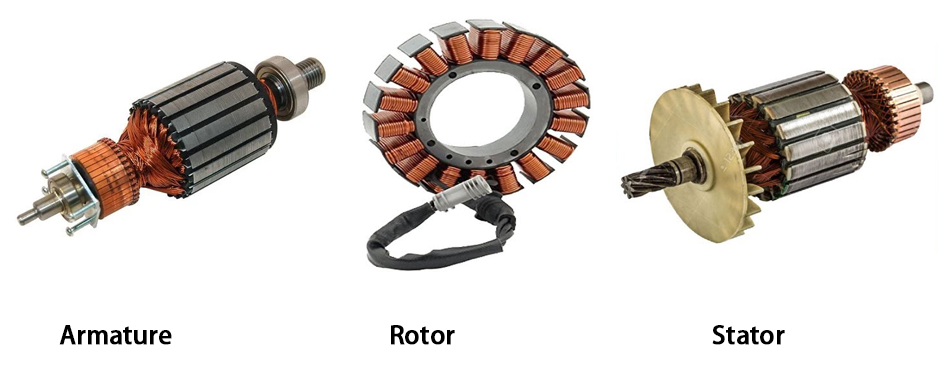

Armature vs Rotor vs Stator

Electrical machines can have an armature, rotor, and stator. The rotor and stator are the main mechanical components, while the armature is the electrical component.

The rotor is the rotating part of the generator or motor. For some generators, it can be a rotating magnetic field or can also contain the armature windings. It is supported by bearings which allow for free rotation.

The stator is the stationary part of a generator or motor surrounding the rotor. It also often contains field windings or magnets vital for creating a magnetic field. They can also have armature windings in some designs.

As for the armature, it is the electrical component that has a winding where the current can be induced or applied. It can be on either the stator or rotor, depending on the design of the machine.

Common Armature Problems and Solutions

Now that you know what is a motor armature, let us look at some of the common problems and how to deal with them.

- A short circuit happens when electrical current finds an unexpected path between coil windings, bypassing the normal resistance. This sudden detour allows too much current to flow, often generating intense heat and potentially damaging the system.

- Open circuits can also happen when there is a break in the winding. This interrupts the current flow and prevents the motor from working.

- Damaged insulation can be due to overheating or wear. With no insulation, expect issues such as shorts.

- Worn commutators can also happen because of friction over time. This can lead to poor contact or sparking.

- Copper drag is when the copper particles from the brushes accumulate on the commuter segments. The dangers of such are ending up with short circuits.

So, what are the solutions?

Rewiring remains a big solution for those who experience short circuits or open circuits. Rewiring the armature with a new wire can resolve most of these issues.

Consider component replacement in cases of damaged commutator segments, bearings, or brushes.

Insulation repair can also be done to prevent the chances of future shorts and ensure the armature operates correctly with proper insulation.

Cleaning and regular maintenance of the commutator and brushes is recommended to address issues of copper drag and flashover.

Conclusion

We have already seen how an armature is an important electrical component of the motors and generators. It is vital for carrying the electrical current that interacts with the magnetic field to produce voltage and torque in generators and motors, respectively. Proper maintenance might be necessary to ensure the best performance. Expect to come across armature winding in many applications, so take good care of the component for improved efficiency and performance.

Please send RFQ , we will respond immediately.

Frequently Asked Questions

What is the purpose of an armature in a generator?

As the armature spins within a magnetic field, it creates an electrical voltage across its coils. This interaction is the core principle behind how generators produce electric power.

What are the main components of an armature?

An armature comprises several parts, which include a metal core, wire windings, a central shaft, and a commutator.

The core is generally built from thin, stacked layers of iron to reduce energy loss from eddy currents, while the windings are made from copper wire for efficient conductivity.

In DC systems, the commutator plays a crucial role in maintaining the direction of current flow. To prevent overheating during operation, many setups also incorporate a cooling fan to help regulate temperature and maintain performance.

What are the common types of windings used in an armature?

Common winding types include lap winding and wave winding. Each is best suited for specific applications based on current and voltage characteristics.