Mastering Control Systems: From Basics to Applications in the Real World

Author:admin Date: 2025-07-07 06:25 Views:216

Introduction

UN control system is a set of mechanical or electrical devices designed to regulate how other systems or devices behave. This is usually done using a control loop so that you have a desired outcome.

We can see that the primary function of a control system is to maintain a certain measurable property near or at a set value, even in the presence of external influences. You should find control systems necessary in automation, industrial processes, and other key applications that involve controlling complex tasks.

Components of a Control System

Whether it is a wireless controller system or a traction control system, they both have some key components that make up the control system. Such include:

Capteur

This is a device that detects if there is a change in the physical quantity, such as the temperature, pressure, or position, and then converts this change into an electrical signal.

Contrôleur

The controller is regarded as the brain of the system. Its job is to receive the signal from the sensor, compare it to the desired setpoint, and calculate the necessary adjustments needed to ensure the system is brought back to the desired state. Once the calculations are done, the signal is sent to the actuator.

Actuator

The actuator in control systems is a device that physically carries out the adjustments as per the controller signal. Once it receives the signal from the controller, it will process it accordingly. For example, it can involve opening or closing a valve, changing the motor speed, or any other process to control the system.

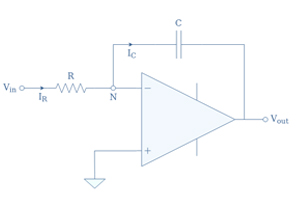

Feedback

Air control systems or any other type may have feedback as a component of the control system. The feedback part provides a process where the system output can be measured, and that information is relayed back to the controller. This is key for the controller to make adjustments depending on the actual output to ensure the system remains on track.

Types of Control Systems

It is possible to come across control systems such as the PID control system, the distributed control system, version control systems, and many others. However, how are they categorized? Below are the main categories of the control systems.

Open-Loop Control System

For this type of control system, the output does not influence the control action. It simply means the system will not adjust its behavior based on the output. It only operates based on a predetermined set of instructions.

Such systems are mostly simple and inexpensive to design and implement. They often cost less as they do not need a complex feedback mechanism or sensors.

Although they are easy and inexpensive to implement, they often have lower accuracy since there is nothing to compare them against the preset instructions.

Examples of such systems include traffic lights, automatic washing machines, a toaster, and a simple gas stove.

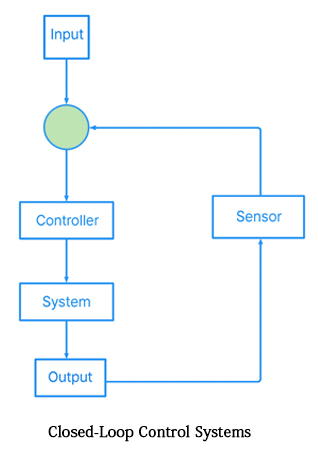

Closed-Loop Control System

In this case, the system uses feedback from the output to adjust the input, thereby maintaining a desired setpoint. In this case, the output is monitored continuously and then compared to the setpoint. If something is off, the controller will adjust the input to minimize the discrepancies.

The advantage of such systems is that you have more accuracy and precision compared to when using open-loop systems. There is also improved error correction, which allows for the automatic correction of errors and disturbances in the system.

It is expected that such control systems will have more stability and make automation perform better. You will also love them because of their flexibility, as they can adapt to changing environments to handle a wide range of conditions.

Examples of such systems include having a thermostat controlling the heating system. The thermostat measures the temperature in the room (output) and then compares it to the setpoint by the user. The signal is sent to the actuator, which can heat the room or stop heating to achieve the desired temperature.

Linear vs Non-linear Control Systems

The two broadly differ based on how the output responds to the input changes. The linear control systems have a proportional relationship between the input and output. So, the change in the output is directly proportional to the input change.

It differs from nonlinear control systems, where the output exhibits unpredictable behavior. It does not follow the principle of homogeneity and superposition but rather experiences hysteresis and saturation.

Linear systems are generally easy to analyze and predict their performance, as they exhibit predictable behavior. Examples include temperature control systems, position control systems, and other similar systems.

The non-linear control system is challenging to analyze and will often require advanced mathematical techniques to get it right. Examples include switches, relays, or systems where a change in operating conditions leads to dynamic changes.

Continuous-time vs. Discrete-time Control Systems

The difference between the two is how they process information. In continuous-time control systems, the signals have values at every point in time within the given interval. They are mostly used in implementing analog components and circuits. Examples include analog filters and systems where physical qualities are continuously monitored and controlled.

Discrete-time control systems work by processing discrete-time signals, which are sampled at specific points in time. They are represented as a sequence of numbers. You can expect to encounter them primarily in robotics, spacecraft control systems, and other applications.

There may be other types of control systems, but the ones mentioned above are the primary ones to help you gain a good understanding of what to expect from control systems.

Applications of Control Systems

Control systems have many applications in our daily lives. Below are examples of control systems in place.

- Manufacturing sectors utilize these systems to control temperature, flow rate, and pressure, which are crucial for ensuring product quality and efficient production.

- The transport sector also uses control systems in applications such as cruise control, braking, steering, and traffic management systems.

- The aerospace industry also needs control systems for its aircraft, satellites, and rockets. They can be used to manage altitude, trajectory, and speed.

- Robots are not new to control systems. A control system enables the robot to perform its tasks with precision and repeatability. This includes industrial automation, surgical procedures, and exploration as well.

- Process control in industries needs such systems for them to maintain key parameters for operation. Such factors include temperature, pressure, and others within the desired ranges for optimal operation.

- Home automation systems, such as smart appliances, thermostats, and security systems, need control systems to automate and run the home environment with ease.

- Energy and power control systems help in power generation, transmission, and distribution. They also help in optimizing power use and efficiency in power grids and plants.

Challenges in Designing Control Systems

Whether you are designing an industrial control system or an inventory control system, the joy comes in when it actually works. However, you may experience a few challenges. Below are some of them and how to deal with them.

– Complexity and Uncertainty

Control systems can quickly get complex depending on how you want them to work. This is especially relevant for large-scale industrial settings, which involve longer development times and increased risk of errors.

Real-world systems often exhibit unpredictable behavior due to factors such as noise, disturbances, and variations in operating conditions. This means that designing controllers needed to handle these uncertainties effectively becomes a challenge.

– System Integration and Compatibility

Many companies often rely on older control systems and only upgrade when necessary. The challenge comes when the older systems are not compatible with the new technologies. This leads to compatibility and integration issues.

Also, it is key to design control systems that offer scalability options. This means they can accommodate changes in the system size or complexity over time.

Make sure compatibility is also enhanced for future integration, even if the current systems do not allow for that.

– Cybersecurity

Sometimes, you may experience vulnerabilities because of cybersecurity issues. This disrupts how the system works and might lead to safety hazards or physical damage, depending on what the control system handles.

It is possible to experience data integrity issues as well. As such, it is vital to protect sensitive data in the control system by limiting access only to the recommended personnel.

– Safety and Reliability

Control systems are crucial in many applications, and their failure can lead to severe consequences. This is why you have to design for safety as well. Ensure that you also rigorously test them to ensure the safety measures will activate when required.

Most people implement a redundancy system to ensure high reliability and fault tolerance as well.

– Human Factors and User Interface

Having user-friendly interfaces makes it easier for those assigned to the system to do their job well. The operators can now easily monitor and control the system.

Training and documentation can also help the operators to use and maintain the control system effectively.

Modern Trends in Control Systems

Control systems are always going to get better and more advanced. Here are examples of modern trends in control systems.

- Control systems are now integrated with AI and machine learning. This includes having predictive maintenance thanks to AI algorithms, which analyze the data from sensors and systems to predict failures and call in for maintenance before it happens.

- The Internet of Things is already happening with control systems. This is where you get enhanced connectivity with various devices that facilitate data sharing, plus remote monitoring capabilities.

- Cloud-based systems are also now available. Such systems enable greater scalability and flexibility, depending on the specific resource needs. Also, you do not have to deal with hardware costs when the system is running in the cloud.

Conclusion

Control systems are key in ensuring the system works within the predetermined set of instructions. This refers to whether the system is of a closed or open loop type. There is always a set of instructions to guide the output to a desired point. Consider the types of control systems available to determine which one best suits your application needs. Ensure regular testing and refinement of the system to achieve the desired output consistently.

Understanding Control System

Veuillez envoyer une demande de devis, nous vous répondrons immédiatement.

Questions fréquemment posées

What are the main components or parts of a control system?

The key components of a control system include the controller, sensor, actuator, and feedback mechanism. These components work together to ensure you always get the desired output.

How are control systems expressed mathematically?

Control systems can be modeled mathematically using transfer functions, state-space representation, and block diagrams. With these tools, you can visualize, analyze, and predict how the system behaves.

How can AI impact modern control systems?

AI and machine learning are now being integrated into control systems to ensure adaptive control, better predictive maintenance, and more intelligent decision-making environments.