What is a Thermocouple? How They Work, Types, and Applications

Author:admin Date: 2025-07-08 10:08 Views:266

- परिचय

- How Does a Thermocouple Work?

- Types of Thermocouples

- Applications of Thermocouples

- Advantages of Thermocouples

- Limitations of Thermocouples

- Types of Thermocouple Insulation

- How to Choose the Right Thermocouple

- Troubleshooting Common Thermocouple Errors

- Alternatives to Thermocouples

- निष्कर्ष

- Video: How Thermocouples Work – Basic Principle + RTD

परिचय

ए thermocouple is a temperature-measuring sensor that consists of two dissimilar metal wires connected to create a junction. Whenever this junction is exposed to heat, a small voltage is generated that correlates to the temperature reading. The voltage is due to the Seebeck effect, where a temperature difference between dissimilar metal wires generates a small voltage.

Its functionality makes a thermocouple applicable in various applications. This includes industrial settings, thermostats, ovens, kilns, and now digital thermometers.

We look at more details about thermocouples, including thermocouple types, how they work, advantages, limitations, and more, to fully understand how best to use them.

How Does a Thermocouple Work?

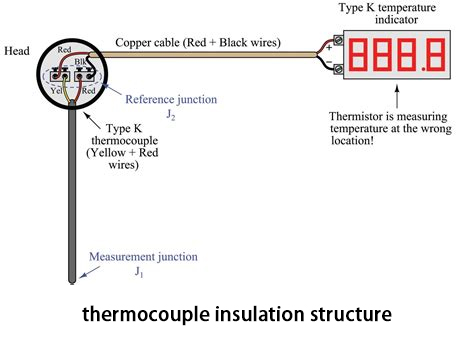

अब जब आप जानते हैं what is a thermocouple, let us look at how it works. The basic principle is that thermocouples have two wires made of different metals that are joined to one end to form a measuring junction.

When this junction is heated, it leads to a small voltage because of the “Seebeck effect.” The Seebeck effect is simply a phenomenon where the temperature difference between two dissimilar electrical conductors leads to a voltage.

This voltage generated is directly proportional to the temperature difference between the cold (reference) junction and the hot (measuring) junction.

The greater the temperature difference, the larger the generated voltage in the thermocouple. This is the working principle, whether it is a water heater thermocouple or a gas fireplace thermocouple.

Types of Thermocouples

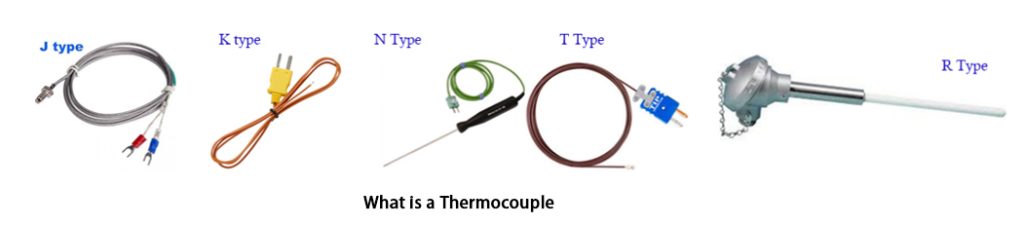

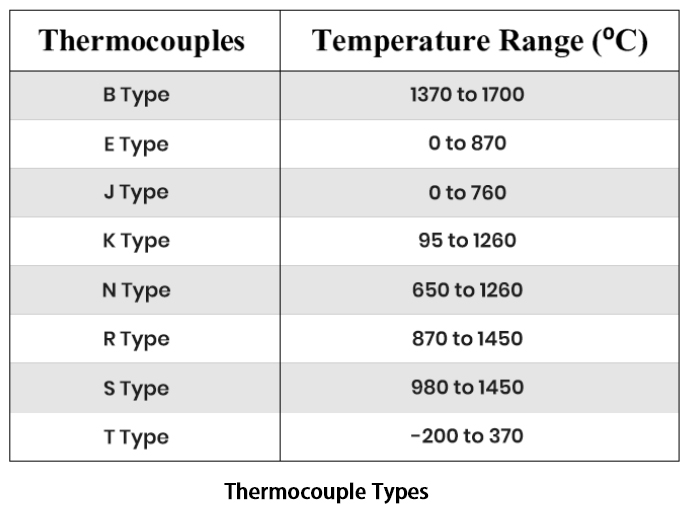

By now, the question of how does a thermocouple work has been answered. Let us look at the types of thermocouples to see which one you can consider for a specific application.

Base Metal Thermocouples

Type J (Iron/Constantan) – it is known for its versatility while being low-cost. These are suitable for general-purpose applications that have moderate temperature ranges. Expect them in a vacuum or inert environment.

Type K (Chromel/Alumel) – This is another widely used type of thermocouple. It is known for its broad temperature range, and you can consider it because it is low-cost and easily available.

Type T (Copper/Constantan) – This type is well-suited for low-temperature applications. It is highly recommended for cryogenic or freezer applications.

Type E (Chromel/Constantan) – This thermocouple offers a high output signal and is accurate in measuring moderate temperature ranges.

Type N ( Nicrosil/Nisil) – This is another good thermocouple with the best stability, even at high temperatures. They are known for having high resistance to oxidation.

Noble Metal Thermocouples

Type R (Platinum/Rhodium 13%) – For this type, it is best used in high-temperature applications where you need high precision and consistency. This ensures that you can handle higher thermoelectric output and achieve long-term stability compared to when using the Type S thermocouple.

Type S (Platinum/Rhodium 10%) – It is similar to Type R, only that it has a lower composition of Rhodium. You can still use it for applications that involve high temperatures as well, without a problem.

Type B (Platinum/Rhodium 30% and Platinum/Rhodium 6%) – This type of thermocouple is designed for very high-temperature measurements and can remain stable up to 1700 degrees Celsius.

Applications of Thermocouples

चाहे वह एक Omega thermocouple or a K-type thermocouple, they are expected to have numerous applications. Here is what to expect.

Industrial applications

Thermocouples can be used for precise temperature control in processes such as tempering, annealing, and quenching, which are crucial to achieving the desired material properties.

Thermocouples can also be used in chemical processing as they help monitor and control temperatures in chemical reactions. This ensures the best product quality and safety.

Food processing is another key application where they can be used in ovens, fryers, and other equipment to help maintain proper cooking temperatures and help prevent spoilage.

Home Appliances

Thermocouple wires can be found in ovens and stoves, where they help regulate and maintain the desired cooking temperatures.

It is the same thing in freezers and fridges, where they ensure consistent temperatures for food preservation.

Hotplates and steam kettles also require thermocouples to monitor and control temperature for cooking and heating purposes.

You can also use a thermocouple for a gas fireplace, which is essential for controlling the heating of a space in the house.

Automotive Industry

This is where the thermocouple can be used in monitoring the engine temperature to avoid cases of overheating.

You can also use it to monitor exhaust gas temperature, helping to optimize engine performance and emissions control.

Medical Field

You can also have thermocouples in the medical field, such as being used to monitor the patient’s body temperature during an operation.

Expect to find them in medical devices such as ablation therapy equipment, which measures the tissue temperature.

These are just some of the commonly used applications of thermocouples. There can be more, and it largely depends on the industry.

Advantages of Thermocouples

- Thermocouples generally offer a wide temperature range for applications. This makes it easier to measure both high and low temperatures with ease.

- They are generally fast in terms of response time. They can quickly react to changes in temperatures, making them suitable for different types of applications.

- They are generally rugged and durable. They can withstand harsh environments such as high pressures, vibrations, and more.

- They are affordable compared to other temperature sensors, such as RTDs. They are also readily available.

- Since they can generate a small voltage depending on the temperature difference, they become self-powered. This means no need for an external power source to make them work.

- Expect more simplicity as they have a simple design, which can be configured in different shapes and sizes to suit the application.

- Depending on the type of thermocouple you choose, they can be quite good at accurately determining the temperature.

Limitations of Thermocouples

- Thermocouples generally have a low output voltage, which can be affected by electrical noise.

- They can be susceptible to noise, especially when used in industrial applications where you have motors and generators.

- Their accuracy can also be limited and can lead to errors sometimes

Types of Thermocouple Insulation

You may wonder why a K-type thermocouple या T-type thermocouple requires insulation. Insulation is important for protecting the thermocouple wires and maintaining their accuracy when working with different temperature measurements. Below are the common thermocouple insulation materials.

PVC (Polyvinyl Chloride) – it is the best for general-purpose insulation. It is relatively inexpensive and offers decent flexibility. However, we do not recommend it for high-temperature applications.

Fiberglass- we recommend it for its high-temperature resistance, low cost, and good flexibility. The downside is that it can be susceptible to abrasion and moisture.

PFA (Perfluoroalkoxy) – This is an excellent choice for applications involving chemical reactions. They also have a high-temperature rating and good electrical properties. They can be, however, more expensive than fiberglass and PVC.

FEP (Fluorinated Ethylene Propylene) – These are similar to PFAs in terms of chemical and temperature resistance. They, however, have slightly lower temperature limits.

Ceramic Fiber – This material provides excellent high-temperature performance, good chemical resistance, and excellent electrical insulation properties. They can be brittle and may require special handling to maintain their optimal performance.

Kapton – These are best suited for high-temperature applications, offering excellent dielectric strength and good mechanical properties. However, they are more expensive than the other insulation types.

Silicone Rubber – This material is suitable for a fireplace thermocouple as it offers high-temperature resistance, flexibility, and good chemical resistance. They might not be the most durable, but they will be good for applications that need more flexibility and high-temperature performance.

How to Choose the Right Thermocouple

If you are going to get a thermocouple for a furnace or a hot water thermocouple, you have to do it right. Below are some of the factors to consider.

Temperature Range

Each thermocouple is designed to operate within a specific temperature range, where it can accurately measure temperatures within that range. For example, you can get the Type K thermocouple for measuring a wide range of temperatures, while the Type T is best suited for lower temperatures.

शुद्धता

Thermocouple accuracy can also vary depending on the type. Type T thermocouple is known for having tight accuracy, while the other types, such as J, K, and N, may have slightly wider error limits.

Chemical Compatibility

The chemical environment can degrade or corrode the thermocouples. This is why you need to consider the sheath material and how it can handle the surrounding chemicals to ensure performance is maintained.

Response Time

Having exposed junctions means a faster response time compared to ungrounded junctions, which are slower. The grounded junctions still offer a good balance between protection and speed. Well, if you need to measure rapid temperature changes, get yourself a thermocouple with faster response times.

Installation Requirements

Consider the thermocouple size and type to see if they are compatible with existing equipment and mounting locations. Also, consider the length of the thermocouple required to reach the desired measurement point and deliver the necessary performance.

Troubleshooting Common Thermocouple Errors

Thermocouples can also experience errors. What is important is that you always know how to resolve them so that they can continue to work correctly. Some of the errors and their solutions include:

Incorrect Thermocouple Type Selection

When you choose the wrong type, such as using a Type J thermocouple in place of a Type T thermocouple, you may end up with inaccurate readings. Ensure that you verify the thermocouple type and that it matches the device settings before making a purchase.

Connection Issues

Issues such as loose, corroded, or damaged connections of the thermocouple or measuring device can lead to a broken connection in the electrical circuit. Start by inspecting all the connections for tightness and cleanliness. Ensure that you have proper contact and insulation. Replace any damaged wires or connectors where possible.

Cold Junction Compensation (CJC) Errors

Sometimes, the reference junction can experience temperature variations, leading to errors. This is why you have to ensure the reference junction is at a stable, known temperature. You could use a heat sink or insulation to minimize temperature fluctuations, which would otherwise lead to errors.

Environmental Factors

Eternal factors such as temperature gradients, electrical noise, vibrations, and humidity may affect readings. The solution is to shield the thermocouple and its wiring, protecting it from electrical noise and extreme temperatures. Use a protective sheath specifically designed for this type of application for optimal performance.

Incorrect Calibration

Sometimes, you may end up with a thermocouple that is not properly calibrated. This means you end up with inaccurate readings. Ensure the thermocouple is regularly calibrated using a known standard for optimal performance.

Alternatives to Thermocouples

Consider using thermistors and resistance temperature detectors (RTDs) as alternatives to thermocouples.

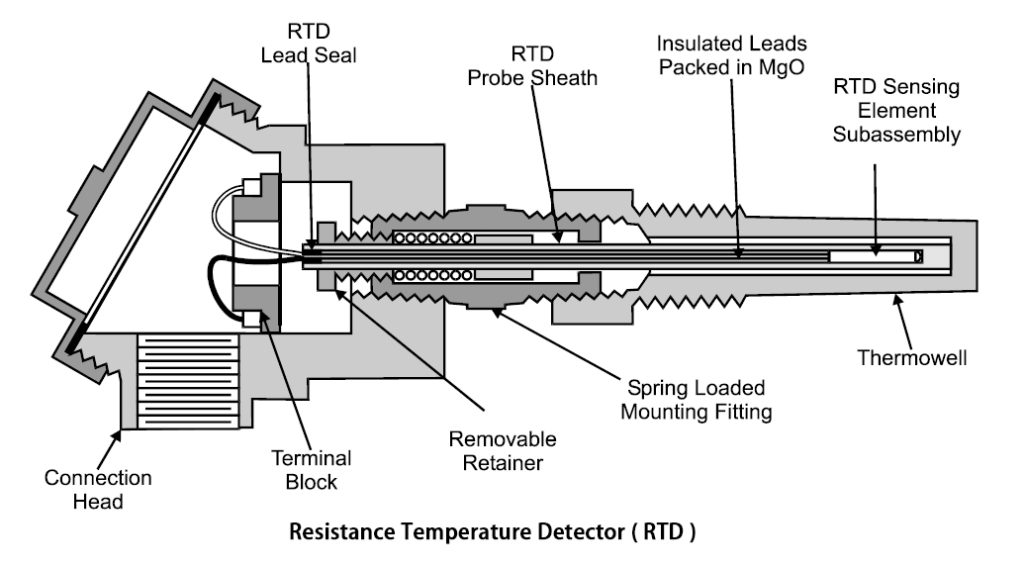

Resistance Temperature Detectors (RTDs)

These work for a wide range of applications, just like thermocouples to measure temperature. Their working principle is based on the electrical resistance of a metal, which changes with temperature.

RTDs use metals such as platinum wire, nickel, or copper. Platinum is the most common because of its stability and accuracy.

People often get RTDs because they offer high accuracy, repeatability, and reliability.

RTDs are generally more expensive than thermocouple, but their response time can be slower than thermistors.

Thermistors

These are great alternatives to thermocouples since they use semiconductor devices where the resistance changes significantly with the change in temperature.

Thermistors are highly sensitive and can detect small temperature variations, making them suitable for precise temperature monitoring.

They are also smaller and less expensive compared to RTDs and thermocouples. You should also expect a faster response time than some thermocouples.

However, thermistors have a narrower temperature range, and also their output is mostly non-linear. This might need linearization.

निष्कर्ष

Thermocouples are essential in many applications that require temperature measurement. This can include freezers, refrigerators, ovens, fryers, and many other appliances. You can also expect to encounter them in home appliances and industrial settings. Regardless of the application, ensure you select a thermocouple that can handle it without issue. That is why we have looked at the different types for you to choose the right one. Also, ensure that you maintain them correctly, such as cleaning, to keep the thermocouple in optimal working condition.

Video: How Thermocouples Work – Basic Principle + RTD

कृपया आरएफक्यू भेजें, हम तुरंत जवाब देंगे।

अक्सर पूछे जाने वाले प्रश्नों

How accurate are thermocouples? The accuracy of the thermocouple largely depends on the type and quality. Most thermocouples will have an accuracy of ±1 to ±2 °C. Regular calibration is also recommended to improve accuracy. Can regular copper wire be used in extending a thermocouple? It is not recommended to do so. Ensure that the thermocouple extension wire is made from the same material as the original thermocouple. Using different metals introduces new junctions, which can lead to measurement errors. What is the lifespan of a thermocouple? The lifespan depends on the operating conditions and usage. Harsh environments may make the thermocouple last only a few months, while it can last for years in low-stress and stable environments.