Current Sensors: Types, Working Principles & Applications

Author:admin Date: 2025-12-16 08:03 Views:27

Introduction

A current sensor is a device used for detecting and measuring the flow of electric current through a conductor and then converting it into a readable signal. It could be an analog voltage, a smaller current, or a digital output.

Current sensors are crucial for controlling, monitoring, and protecting electrical systems in a wide range of devices, including electric vehicles, smartphones, and industrial machinery.

How Current Sensors Work

Current sensors work by detecting the change caused by the electricity flow. It can be a tiny voltage drop across a component or the generation of a magnetic field around the wire. The current sensor is responsible for converting the change into a measurable signal.

There are two main ways current sensors work. It can be direct sensing or indirect sensing.

- Direct Sensing or Contact-Based

This is the most cost-effective and straightforward method. It uses a shunt resistor, which offers high precision and a low resistance component placed in series with the current path.

When the current flows through the shunt resistor, a small voltage drop is created across its terminals. The system uses Ohm’s law (I = V/R) to calculate the current based on the measured voltage.

Since the sensor is connected to the circuit, it does not provide electrical isolation. This makes it dangerous to use in high-voltage systems.

- Indirect Sensing (Magnetic Field)

In this method, the current sensor detects the magnetic field that naturally surrounds a conductor carrying current. It is called non-contact because the sensor does not need to be electrically connected to the circuit.

Hall-effect sensors are the most common magnetic-sensing technology. In this case, a semiconductor is placed near the conductor. A magnetic field forms when current passes through the conductor. The electrons move to one side of the element, which creates a tinary voltage difference called the Hall voltage.

The Hall voltage is then amplified and processed to represent current flow.

Key Performance Parameters of Current Sensors

These are the technical metrics used for evaluating how a current sensor would be useful for an application. Here are the most critical parameters for choosing a current sensor.

Accuracy and Linearity

Accuracy measures how closely the sensor’s output matches the actual current. High-precision sensors such as Fluxgate sensors can achieve errors as low as 0.001%, whereas general-purpose Hall-effect sensors may have precision ranging from 0.5% to 5%.

Linearity is the sensor’s ability to maintain a consistent proportional output across the entire range. When linearity is high, system calibration is simplified because the output signal directly correlates with the input, eliminating the need for complex software compensation.

Measurement Range and Sensitivity

The range is the span between the minimum and maximum current a sensor can detect accurately. Choosing a range that is too broad reduces precision for small current changes.

Sensitivity is the slightest change in current that results in a detectable change in the output signal. High sensitivity is vital for detecting tiny fluctuations in battery-powered or low-power devices.

Bandwidth and Response Time

The bandwidth indicates the frequency range over which the sensor can accurately measure. Modern current sensors can support a wide range of bandwidth, making them ideal for high-speed switching in EV chargers and solar inverters.

The response time is the time it takes for the output signal to reflect a change in the input current. Fast response times are essential for applications such as overcurrent protection to prevent equipment damage.

Electrical Isolation

This is also called galvanic isolation. In this case, it is the physical separation between the high-voltage primary circuit and the low-voltage sensing circuit. You will need such an isolation for high-voltage applications, such as an 800V EV battery. The aim is to ensure safety and protect the control electronics.

Temperature Stability and Drift

Thermal drift is the change in accuracy or zero point caused by temperature fluctuations. In 2025, you can now find zero-drift architecture that maintains stability across a wide operating range.

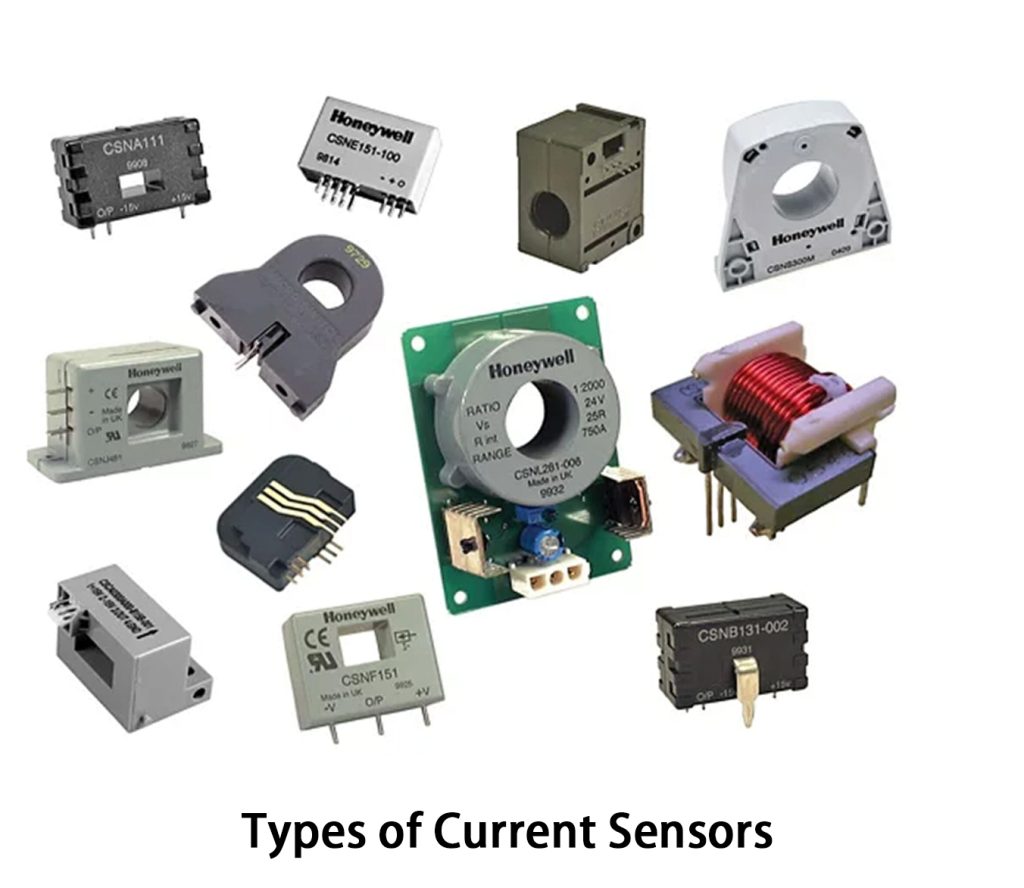

Types of Current Sensors

Expect to come across multiple types of current sensors in the market. Here are the most common options to consider.

Hall Effect Current Sensors

This one works via the Hall Effect, in which a magnetic field perpendicular to a current-carrying semiconductor creates a transverse voltage. This voltage is proportional to the magnetic field generated by the primary current.

This type of sensor provides galvanic isolation, has no insertion loss, and can measure both AC and DC.

The downside is that it can be susceptible to external magnetic interference and temperature-induced offset drift.

Shunt Current Sensors

A shunt current sensor is a high-precision, low-resistance resistor that is placed in series with the load in the circuit. It uses Ohm’s Law, where the voltage drop across the resistor indicates the current.

These sensors are considered high-accuracy current sensors. However, high current leads to some power loss. It is therefore important to do careful thermal management to prevent heat dissipation from affecting accuracy.

Eddy Current Sensors

These sensors use electromagnetic induction for detecting the changes in magnetic fields. They are primarily used as displacement sensors to measure the distance to a conductive target; they are still used to detect current flow by measuring the secondary fields produced by eddy currents.

Their rugged, non-contact nature makes them useful for deep-sea current sensors or heavy industrial environments where dirt, high pressure, or oil can destroy the standard contact current sensors.

Current Transformer (CT) Sensors

In this case, an alternating current sensor works on the principle of Faraday’s law of induction. So, the primary current creates a magnetic field that induces a proportional, but smaller current in the secondary windings.

Common types include solid-core and split-core current sensors. The solid-core is the most accurate and must be installed during initial wiring. As for the split-core current sensor, it has a clip-on design that allows it to be retrofitted for energy monitoring without cutting existing wires.

Rogowski Coil Current Sensors

An air-cored (non-magnetic) coil is wrapped around the conductor. It measures the rate of change of current, which can then be integrated to find the current value.

Since they lack an iron core to saturate, they are ideal for high-voltage current sensing, which is vital for measuring massive surges or high-frequency transients in power electronics.

Fluxgate Current Sensors

These current sensors offer ultra-high precision. They are known to use a saturable core and a compensation winding to maintain zero flux in the core.

Because of how well they perform, they are the best for aerospace systems, MRI machines, lab-grade power supplies, and more. They keep offering stability and accuracy better than Hall Effect technology.

Tunnel Magnetoresistance (TMR) Current Sensors

TMR sensors utilize a quantum-mechanical effect in which electrons tunnel through a thin insulating layer between two magnetic layers.

People can choose TMR current sensors over Hall sensors because they offer higher sensitivity, lower power consumption, and higher bandwidth.

Key Applications of Current Sensors

Current sensors are vital to modern electrical infrastructure. Here are the key applications of current sensors.

Electric Vehicles (EVs) and Transportation

The automotive sector is the biggest driver of current sensor innovation. As of 2024, over 25 million EVs are using advanced current sensors.

We have the current sensors in the battery management system to monitor the charging and discharging rates of the battery packs. This information is used to calculate the state of charge and state of health. Such prevents overcharging, extends battery life, and ensures safety through the detection of overcurrent faults.

The sensors are also used in controlling the motor and inverters. Here, high-speed sensors provide real-time feedback to traction inverters, enabling them to control motor speed and torque more efficiently.

Sensors in fast-charging stations monitor high current to prevent thermal overload and ensure accurate billing.

Renewable Energy and Smart Grids

Many countries right now have invested a lot in green energy. The current sensors are crucial in managing such decentralized power sources.

Solar & wind inverters use the current sensors to monitor the output of panels and turbines. This optimizes the Maximum Power Point Tracking (MPPT) and the conversion of DC power to AC.

Smart grids also include current sensors to help balance supply and demand in real time by detecting transients or fault currents that could destabilize the network.

Energy storage systems also need current sensors to manage energy flow into massive battery banks. This ensures efficient storage of excess solar or wind power.

Industrial Automation and Robotics

Current sensors are also important in industrial automation. They make it possible for machines to be self-monitoring and proactive.

Predictive maintenance is where AI-enabled systems use data from current sensors to analyze anomalies in motors and actuators and predict mechanical wear or other impending failures, enabling timely correction.

Also, current sensors provide precise current feedback for robotic arm movements and help ensure safety in cobots by detecting unexpected collisions.

Consumer Electronics and Smart Homes

Miniaturized sensors are increasingly embedded in the devices we use daily to improve safety and energy efficiency.

For example, smartphones and laptops use current sensors to manage the battery health and fast-charging cycles.

Smart appliances such as washing machines and refrigerators use current sensors to detect a sausage pattern and report on energy use to home management apps.

You can also find leakage current sensors in home circuits to provide critical protection against electric shocks and electrical fires.

Medical and Scientific Equipment

High-precision current sensors are vital in specialized fields that require extreme accuracy.

Medical devices such as MRI machines and ventilators rely on current sensors to maintain stable power supplies and precisely control electromagnetic fields.

Ultra-precise fluxgate sensors are used in labs for calibrating other electrical instruments.

How to Choose the Right Current Sensor

Choosing the right current sensor requires balancing technical parameters against the specific needs you have to address. Here is how to finalize your selection.

- Understand the primary measurement constraints

The current type can determine which current sensor you can buy. If you need to measure DC, you are limited to TMR, fluxgate, Hall-effect, and shunt sensors. For AC-only applications, we recommend Rogowski coils or CT sensors, as they are more cost-effective.

The current range is also important. Determine the maximum and minimum current to understand which rent sensor works best. For high currents, it is best to use indirect sensing to avoid excessive heat generation when using shunt current sensors.

Do you have isolation requirements? For those who need to measure high-voltage lines, it is vital to have an isolated sensor to protect low-voltage control electronics. TMP and Hall-effect sensors are inherently isolated. If you have to use shunt resistors, then make sure there is an additional isolation amplifier.

- Evaluate Dynamic Performance

In this case, look at the bandwidth and response time.

Bandwidth is essential for systems with high switching frequencies. The standard Hall-effect sensors can handle up to 200 kHz. Modern high-frequency power electronics require TMR sensors or high-bandwidth shunts capable of exceeding 50 MHz.

As for response time, it is critical to enhance the overcurrent protection capabilities. If your system must shut down in microseconds to avoid damage, look for current sensors with response times of less than 1 µs.

- Assess Accuracy and Thermal Stability

High-precision tasks, such as battery monitoring in a BMS, require current sensors with an error of less than 1%. Shunt systems and fluxgate sensors are the best choices for ultra-precision.

Thermal drift is also vital to consider. Traditional hall sensors can drift a lot over their lifetime and with temperature. However, you can still get modern zero-drift hall sensors or shunt resistors with low temperature coefficients being used for automotive applications.

- Integration and Mechanical Factors

The form factor is important to know where best to fit the current sensor. If the space is tight, consider the TMR ICs or in-package Hall sensors to reduce the sensor footprint by up to 5 times compared to shunt sensors.

You can choose between through-hole and surface-mount, depending on the available space and the application.

Common Current Sensor Problems and Solutions

Troubleshooting the current sensors helps you understand the problem and the right solution for it. Here are the common current sensor problems and solutions.

Inaccurate Readings and Drift

Inaccuracies can be attributed to under-reporting, zero drift, and over-reporting. This happens because of aging components, residual magnetism in the core, or extreme temperature fluctuations.

Solution:

Perform periodic recalibration using high-precision reference current. For magnetic sensors, use degaussing procedures to help remove residual flux.

Modern software is in place that you use to detect and compensate for drift in real time.

Overheating and Thermal Stress

Excessive heat is a primary cause of sensor failure. This is particularly true in shunt-based and automotive systems.

High currents generate significant heat, especially in shunt resistors. This can change the material’s resistance and lead to a thermal runaway loop.

Solution:

Use resistors with a low temperature coefficient of resistance (TCR). Still, increase the copper area around the sensor and include thermal vias to dissipate heat to other layers.

Many high-power designs use magnetic sensors to avoid the heat generated by contact-based shunts.

Magnetic and Electrical Interference

Magnetic sensors are susceptible to their surroundings. This easily leads to noisy or fluctuating outputs. Things like transformers, high-voltage lines, and motors can generate stray magnetic fields that distort the sensor’s readings.

Solution:

We recommend using shielded cables and physical magnetic shielding around the sensor. Also, implement differential measurements or low-pass filtering in the software to help attenuate unwanted electrical noise or interference.

Core Saturations

Saturion occurs whenever the magnetic material can no longer handle an increase in current. This causes the output signal to have a flat top and lose accuracy. Such a problem arises when you expose a CT current sensor to current levels beyond its design limits.

Solution:

Select sensors having a high knee-point voltage. You can still use specialized sensors designed to handle DC offsets.

To recover a saturated CT, apply a decaying AC current to help reset the magnetic domains.

Connection and Installation Issues

Sometimes, simple mechanical failures can remain a leading cause of zero output or erratic behavior of the current sensor.

Solution:

Inspect the wiring regularly for oxidation and ensure all connections are tightened to the manufacturer’s torque specifications.

Conclusion

Current sensors have evolved a lot from simple measuring components into highly sophisticated devices that help manage the devices we use daily. It is important to always choose the right current sensor depending on the application. It is not just about the Amps, but also the balancing speed, accuracy, durability, and much more. Of course, always buy from a top-rated brand.

Please send RFQ , we will respond immediately.

Frequently Asked Questions

Is there a difference between AC and DC current sensors?

AC current sensors are used to measure alternating current and use current transformers or Rogowski coils. As for DC currents, they are used to measure direct current and typically use shunt, fluxgate technologies, and shunt resistors.

What is a battery current sensor?

A battery current sensor is used to monitor the charge and discharge current of a vehicle or its energy storage system. The sensor helps manage the charging efficiency, protect batteries, and detect faults in automotive and renewable energy applications.

What is a clamp-on current sensor?

A clamp-on current sensor measures current by clamping around a wire. Such a sensor is used mainly for maintenance, troubleshooting, and portable measurements.