What Is a Fiber Optic Cable? A Beginner’s Guide to High-Speed Connectivity

Author:admin Date: 2025-08-09 02:45 Views:129

- Введение

- What Is Fiber Optic Cable Made Of?

- Types of Fiber Optic Cables

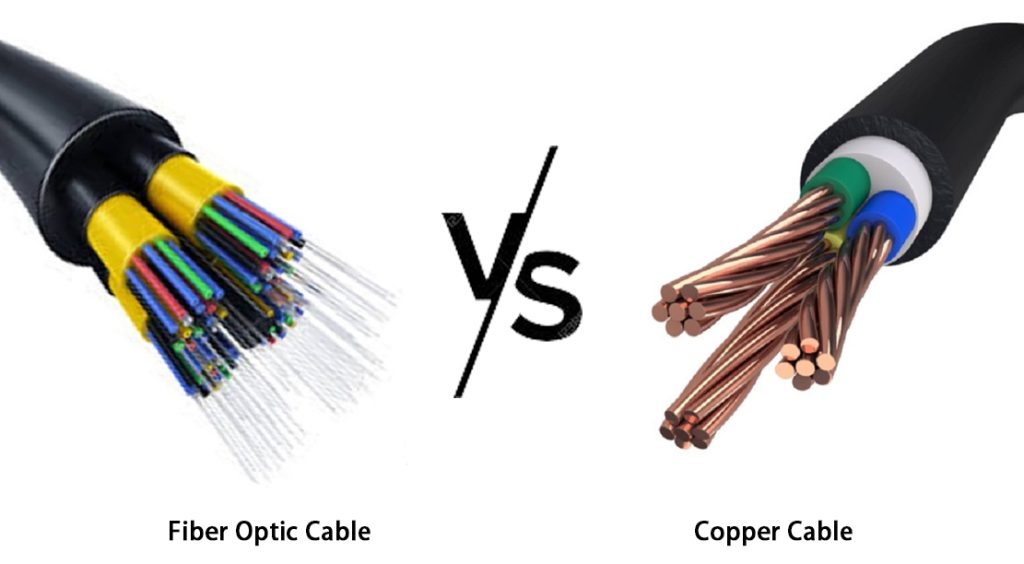

- Fiber Optic Cable vs Copper Cable

- Common Applications of Fiber Optic Cables

- Advantages of Fiber Optic Cables

- Limitations of Fiber Optic Cables

- Fiber Optic Cable Installation Process

- Fiber Optic Cable Maintenance

- Заключение

- Video: Optical fiber cables, how do they work?

Введение

А fiber optic cable is a type of network cable used for transmitting data as light signals through thin strands of plastic or glass, which are also called optical fibers. These cables offer a high bandwidth and can transmit over long distances with minimal signal loss. Such a feature makes them the best for high-speed internet, television, and phone services.

Fiber optic cables have been around for a while now, and many companies offering internet and telecommunication services have widely adopted them. Expect to encounter many other applications as we delve deeper into understanding fiber optics better below.

What Is Fiber Optic Cable Made Of?

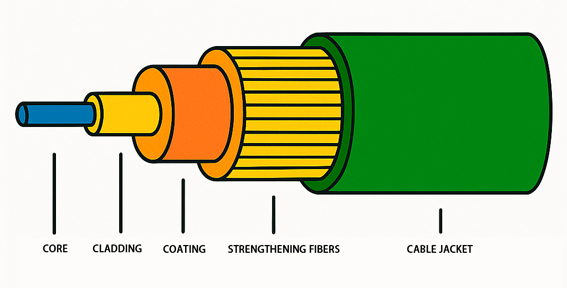

А fiber optics cable will be made of glass or plastic as the primary material. It consists of the core, cladding, and a protective outer jacket as the parts.

Core

The core is the central part of the optical fiber cable where the light pulses travel. It is usually made of glass or plastic. Glass fibers are best for long-distance and high-performance applications since they have lower signal attenuation.

The plastic fiber optic cable for the internet is more suitable for short distances and less demanding uses.

Cladding

This is the layer surrounding the core. It is made of a material with a lower refractive index compared to the core. The work of the refractive index is to keep the light signals from moving out of the core; as such, they do not escape into the surrounding environment.

Just like the core, the cladding will also be made of either plastic or glass.

Coating

An additional layer of coating, mostly made of acrylate, is applied to the cladding to offer protection.

The coating is vital to prevent moisture, scratches, and other environmental factors from damaging the fiber. It also allows for flexibility and cushioning of the fiber.

Jacket

This is the outermost layer of the fiber optic cable. Its job is to provide primary mechanical and environmental protection of the cable. It will be made of materials such as PVC or polyethylene.

The jacket also protects the fiber cable against UV radiation, physical damage, and moisture.

Types of Fiber Optic Cables

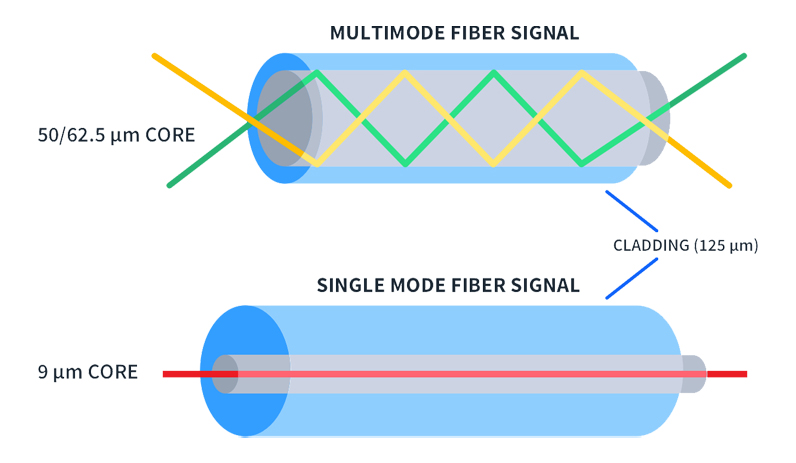

Фiber optic cables are divided into two types: single-mode and multimode.

Single-Mode Fiber (SMF)

The core of the single-mode fiber is very small, with a diameter of 9 microns. This allows propagation of only one mode of light at a time.

This type of construction is best suited for long-distance communication. As a result, it can reach hundreds or even thousands of kilometers.

Expect to come across a high bandwidth with this type of fiber optic cable. Such a feature is what you need to transfer a large amount of data over long distances.

Examples include the OS1 and OS2, which are common designations for single-mode fiber. The OS2 is the current standard for those who want superior speed and performance.

Multimode Fiber (MMF)

В этом случае fiber optic ethernet cable has a larger core, allowing multiple light modes to be propagated simultaneously. Since you are propagating multiple light paths, such a construction is more susceptible to signal distortion, so it is best suited for shorter distance runs.

It is generally more cost-effective when used for shorter distances compared to single-mode fiber. For example, you can use it for local area networks or wiring data centers.

The common multimode fiber types are OM1, OM2, OM3, OM4, and OM5. Each type has varying core sizes and different performance characteristics.

Fiber Optic Cable vs Copper Cable

Fiber optic cables and copper cables are both used for data transmission, with significant differences in cost, reliability, bandwidth, and speed.

Fiber Optic Cable

In this case, light signals are used for data transmission, leading to higher speeds and bandwidth.

Fiber optic cables are faster than copper cables in speed and bandwidth. Their current capabilities are expected to reach 100Gbps and beyond.

Another reason someone would pick fiber cable is that it transmits data over long distances with minimal signal loss because of its lower attenuation.

The signal is also not affected by electromagnetic interference (EMI), which is important if you have to transmit data in environments with a lot of electrical interference.

We also find fiber cables to be less prone to security breaches such as signal interference.

The biggest downside is the cost. They are generally more expensive than copper cables. However, over the years, the price has significantly come down, making them more competitive.

Copper Cables

Data transmission in this case uses electrical signals rather than light pulses, as in fiber optic cables.

However, the speed is limited. Sometimes, you can only get speeds of around 1Gbps, which is nothing compared to fiber optic cables.

Signal degradation will be worse over longer distances. It does require repeaters or signal amplifiers.

The cables are also susceptible to EMI, which affects the transmission speed and data integrity. By extension, copper cables are also more vulnerable to signal interception.

These cables are less expensive than fiber optic cables. We recommend them only for shorter distances and simpler network setups.

| Особенность | Fiber Optic Cable | Copper Cables |

|---|---|---|

| Data Transmission | Light (photons) | Electricity |

| Speed and Bandwidth | Higher | Lower |

| Distance | Longer | Shorter |

| EMI Susceptibility | Not susceptible | Susceptible |

| Расходы | Higher | Lower |

| Приложения | High-speed internet | Local area networks |

Common Applications of Fiber Optic Cables

Whether it is the Corning fiber optic cable or any other popular brand, they all have the same applications. This includes:

Телекоммуникации

This is where fiber optic cables are used for internet and phone services. These cables are the backbone of telephone and internet networks, ensuring that they provide high speeds and reliable connections for homes and businesses.

We also find them useful in cable television. This ensures high-quality video transmission, such as HDTV, CATV, and other video-on-demand services.

Data centers would also use fiber optics to connect servers and users in data centers. As such, there is faster data transfer and efficient network performance.

Нетворкинг

Fiber optic cables connect computers and devices within a local network, leading to high-speed communication between the connected devices. In addition to local area networks, they can also be used for wide-area networks to create large-scale networks connecting multiple locations.

Industrial and Commercial Applications

Fiber optic cables can also be used in industrial automation. They can transmit data and control signals in industrial environments. If electromagnetic interference (EMI) is a concern, fiber optic cables do a better job.

Fiber optic cables, along with sensors, can also be used to measure temperature, pressure, and other variables in industrial settings.

Medical Applications

Фiber optic cabling is also used in medical applications. For example, endoscopy equipment uses fiber optic cables to allow the doctor to view internal organs and body cavities, minimizing the need for invasive procedures.

Другие приложения

Fiber optics are also used in the aerospace industry, allowing communication, navigation, and control systems.

The same technology is also used in defence and security operations. This includes submarines, hydrophones for sonar, and other related defense applications.

Decorative lighting in homes or commercial spaces can use this technology for giving off vibrant and energy efficient lighting options.

Advantages of Fiber Optic Cables

- They offer higher bandwidth and faster speeds

- They are good for long-distance signal transmission

- Expect better reliability since signal degradation is minimal

- Comes with greater security as it is harder to intercept the data

- It is lightweight and thin, making it easier to install and manage

- Lower maintenance needs are required since they are more durable

Limitations of Fiber Optic Cables

- They can be more fragile since they are made of glass, so proper handling is recommended

- Installing fiber optic cables requires specialized equipment and knowledge

- The initial cost is higher, including the cost of the cables and associated equipment

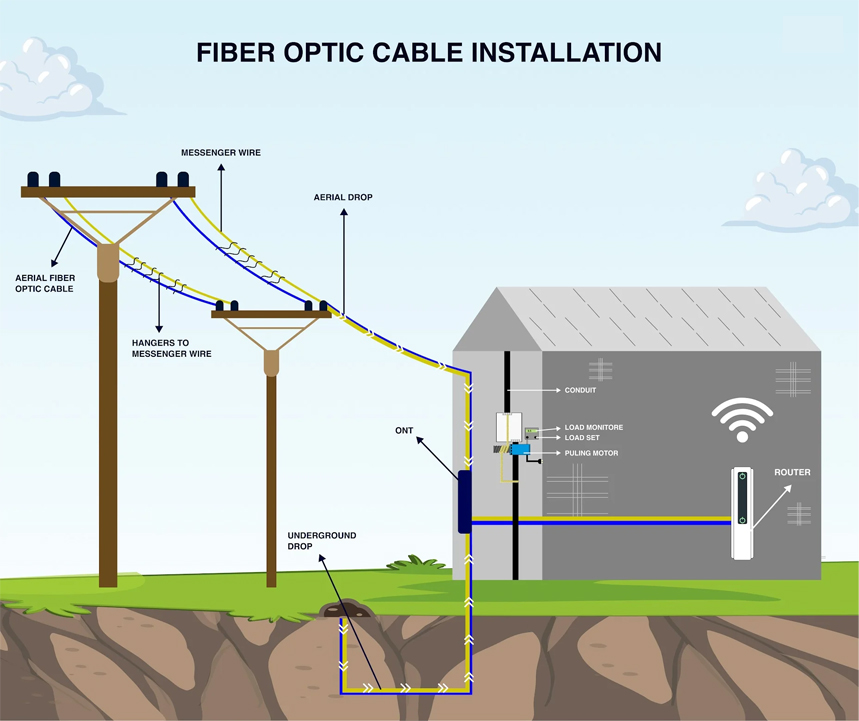

Fiber Optic Cable Installation Process

The various types of fiber optic cables all have a similar installation process, which we will look at below.

1. Planning and Survey

Site assessment is important to ensure that the project is handled properly. This includes having technicians evaluate the physical environment, potential routes for the cable, and other existing infrastructure.

A detailed plan has to be created to determine the best route possible considering the current and future bandwidth needs.

Also, what are the necessary permits to run the cable based on the proposed routes.

2. Cable Preparation

Fiber optic cables are carefully prepared for termination and splicing. This involves stripping the outer jacket to access the individual fibers in the cable. Cleaning can also be done to ensure optimal signal transmission.

3. Deployment

In many cases, trenches can be dug to allow fiber optic cabling or sometimes the companies can use the existing conduits.

The cables are then pulled through the innerducts or conduits to get to their destination.

Aerial installation is also possible. This is where cables are strung between poles and secured using specialized hardware.

4. Splicing and Terminating

There are various ways of splicing fiber optic cables. Examples include fusion splicing and mechanical splicing. In fusion splicing, fibers from different cable sections are joined using a fusion splicer, resulting in a low-loss connection.

You can also use mechanical splicing, where mechanical connectors join the fibers.

Connectors are attached to the fiber cable ends so you can now connect to the network equipment.

5. Testing

Testing fiber optic cable types is important to ensure they are working. A common test is the OTDR testing feature, which measures the signal strength and identifies any breaks or losses in the fiber. This method can pinpoint the exact location of the issue.

Power meter testing can also be used to verify signal levels and ensure proper operation.

6. Connecting to the Network

Once the tests are done, you can connect the customers to the network. One option is to use the Optical Network Terminal, which is useful for converting the optical signal to an electrical signal. This signal is more usable for modems, routers, and other devices.

Fiber Optic Cable Maintenance

How you care for and maintain fiber optic cables can help improve their overall performance and determine when they need to be repaired. Here are some key maintenance practices.

- It is recommended that the adapters, connectors, and transceiver ports be cleaned regularly. Use lint-free wipes to help prevent contamination and ensure optimal light transmission.

- Inspect the cables for kinks, bends, or any other signs of physical damage. Also, check the connectors for discoloration or cracks.

- Cable management is also important to ensure that the cable does not bend or twist, which could lead to issues.

- Regular testing, such as OTDR tests, is recommended to identify potential issues such as high attenuation or faulty splices.

- Maintain detailed documentation of the fiber optic structure in place, including the cable routes, connection points, and testing results. This is vital to aid in troubleshooting and future upgrades.

Заключение

Compared to other similar technologies, it is easy to see why companies would switch to fiber optic cables. You can expect better speeds and bandwidth compared to using copper wires. Also, they are not easily affected by EMI and can transmit data over long distances without signal degradation. Yes, they might have a slightly higher initial cost, but the advantages of fiber optic cables outweigh the cost downside. Just make sure professionals do the installation to experience the best performance.

Video: Optical fiber cables, how do they work?

Пожалуйста, отправьте запрос предложения, мы ответим немедленно.

Часто задаваемые вопросы

How deep is the fiber optic cable buried?

It all depends on where the cable is passing through. It can be buried as deep as 12 to 48 inches. For urban areas with paved roads, expect a shallower burial depth, but high traffic zones usually need a deeper burial depth.

How do you splice fiber optic cable?

The splicing process requires specialized machines to do the job. First, you have to prepare the ends correctly and align them precisely. Lastly, fuse them together by using a fusion splicer. This process ensures you have minimal signal loss at the splice point.

How much does fiber optic cable cost?

The cost largely varies by brand and location. You will get most having a cost of $0.09 to $1.53 per foot. Look at the cable specifications to see if it is the one you need before buying, as they vary a lot.