What Is a Thermistor? Working Principle, Types, and Applications

Author:admin Date: 2025-07-11 06:24 Views:285

- 介紹

- How Do Thermistors Work

- Key Characteristics of Thermistors

- How Thermistors are Made. Materials Used.

- Thermistor Circuit Configurations and Usage

- Applications of Thermistors

- Advantages and Limitations of Thermistors

- How to Choose the Right Thermistor

- How To Check a Thermistor

- 結論

- Video: Thermistor Basics – NTC PTC

介紹

一個 thermistor is a semiconductor device whose electrical resistance varies depending on the temperature. The name thermistor comes from the combination of the terms thermal and resistor. That is why thermistors are commonly used as temperature sensors and to control current as a function of temperature.

Thermistors differ from regular resistors in that their resistance is highly sensitive to temperature changes. This makes them useful for different applications that might require measuring temperature changes.

Other than temperature measurement, the same can be used for temperature compensation, overload protection, inrush current limiting, and many other applications, depending on the use.

Let us look at more details about thermistors, how they work, the types, applications, and many others.

How Do Thermistors Work

A thermistor sensor is temperature sensitive, meaning its electrical resistance largely changes with temperature. They are mainly categorized into two types, which help us see how the thermistor works. This includes the Positive Temperature Coefficient (PTC) and Negative Temperature Coefficient (NTC) thermistors.

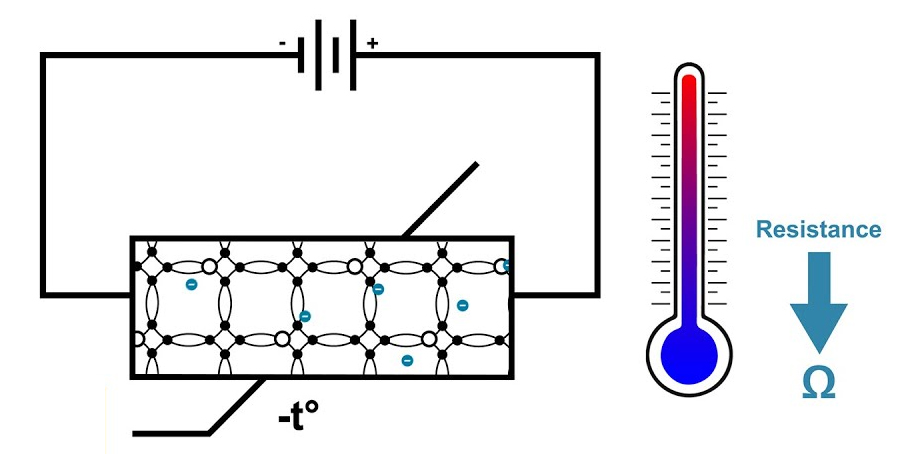

NTC Thermistors

In the case of NTC thermistors, an increase in temperature leads to an increase in the availability of charge carriers, or electrons. The result is having a higher electrical conductivity and thus lower resistance. This feature makes the NTC thermistor ideal for applications where temperature measurement and control are important.

PTC Thermistors

一個 PTC thermistor works differently, whereby an increase in temperature also increases the resistance. This behavior makes it a good choice for overcurrent protection applications or as a resettable fuse in electronic circuits.

Key Characteristics of Thermistors

Thermistors are generally good for various temperature-related applications. Below are some of the features that make them stand out.

Fast Response Time

Thermistors can quickly react to temperature changes, which is important for some applications. The change can typically range from milliseconds to seconds. This rapid change is possible because of their thermal capacity and small size. This allows them to track the temperature fluctuations closely.

Temperature Measurement Range

Thermistors are built with different capacities. This makes it possible to have a variety of temperature range measurements. For example, you can come across some designed to work with cryogenic temperatures (-273 degrees Celsius) while others can handle high temperature applications with temperatures exceeding 300 degrees Celsius.

Compact Size

Thermistors can be manufactured in small sizes, which makes them ideal for applications where space is limited or you have to monitor temperature at specific points.

Cost-Effectiveness

Looking at the production costs of thermistors, you should find them cost-effective compared to some other options. This makes them a popular choice for many cost-sensitive applications.

Non-Linearity

無論是 PTC thermistor 或者 NTC thermistor, they all tend to have a non-linear relationship between resistance and temperature. This calls for careful calibration in some applications to end up with the correct functionality.

Material Dependence

The performance of a thermistor is also influenced by the materials used in its construction. For example, you can come across thermistors made of metal oxides such as manganese, iron, cobalt, and nickel.

How Thermistors are Made. Materials Used.

Thermistors are primarily made from semiconducting metal oxides. Examples include cobalt, iron, nickel, and manganese oxides. The oxides are combined with a binder and shaped into discs, chips, or beads, and then sintered at high temperatures to end up with a stable ceramic body.

The metal oxides are the core material for thermistors. Using binders is crucial for holding the metal oxide grains together, allowing for a cohesive structure. An example of a binding agent includes alumina.

It is also possible to use a stabilizing agent as well. This is to improve the overall stability and performance of the thermistor.

Once shaping is complete, the thermistor will be encapsulated with glass or epoxy to protect it further and enhance electrical insulation, ensuring optimal performance remains.

Thermistor Circuit Configurations and Usage

A thermistor can be used in circuits differently to achieve a particular functionality. That is where circuit configurations come in handy. Examples of common configurations for thermistors include bridge circuits, voltage dividers, and operational-amplifier circuits.

Voltage Dividers

You can use a thermistor with a fixed resistor connected in series with a voltage source to act as a voltage divider. The voltage across the thermistor changes depending on the temperature variations. This provides a voltage output proportional to the change in temperature.

Bridge Circuit

A thermistor can also be used as one leg of the Wheatstone bridge. When the thermistor resistor changes, the balance of the bridge circuit also changes. This leads to the production of a voltage signal that can be amplified and measured.

Op-amp Circuits

Op-amps are commonly used to amplify, linearize, or buffer voltage signals from a thermistor circuit. This enhances measurement accuracy and gives a more stable output.

Applications of Thermistors

無論是 dryer thermistor 或 fridge thermistor, they are all important in various capacities. Here is what to expect as the common applications for thermistors.

Temperature Sensing and Measurement

Thermistors are widely used as temperature sensors in many devices. It can be domestic appliances such as microwaves, ovens, and others, or the automotive sector, where they can measure the engine coolant temperature.

Digital thermometers also have thermistors as the core components for accurate temperature readings. Some medical devices can also use thermistors for their operations. Examples include dialysis equipment and patient monitoring systems.

Temperature Compensation

Thermistors can also be used to compensate for temperature variations in different types of circuits. The result is having a stable performance for a device.

Inrush Current Limiting

The NTC thermistors are often used for inrush current limiting applications. This is common in power supplies so that the sensitive components are protected from damage during startup.

Overcurrent Protection

Yes, you can use the thermistors for overcurrent protection in electronic circuits. This is because they act as self-resetting fuses.

Heating and Cooling Systems

Thermistors can also be vital in HVAC systems. This is where they help with controlling and maintaining your desired temperatures.

Industrial Processes

You may also come across thermistors in industrial applications. This includes chemical reactors, semiconductor manufacturing, and plastic molding. So long as temperature measurement and control are necessary, a thermistor can be used.

Advantages and Limitations of Thermistors

Advantages

- They offer high sensitivity to changes in temperature

- Fast response time

- Low cost compared to other temperature sensors

- Compact size to work well in tight spaces

- Highly versatile as they can work in different industries

- They are quite rugged to handle different environments

Limitations

- Tends to have non-linear resistance characteristics

- They can experience self-heating

- Linearization can be a challenge sometimes

How to Choose the Right Thermistor

When you decide to opt for a thermistor as a temperature sensor, there are several key considerations to take into account. Here is our comprehensive list to keep in mind.

Define Your Needs

Start by defining your needs, which include the temperature range. This is vital for determining the minimum and maximum temperatures the application can handle.

Focus on the accuracy as well. This defines the level of precision needed for temperature measurement.

The response time of the thermistor is important, as it indicates how quickly the thermistor reacts to temperature changes.

The size and form factor are particularly useful, as they enable the selection of the correct physical size of the thermistor for a given application.

Understand the Thermistor Types

There are various types of thermistors, and each works differently. Once you understand their working principles, you will know which one to choose for your application.

The main types are the NTC and PTC thermistors. The NTC thermistors work by having their resistance reduce as the temperature increases. You would then use them mostly for temperature control and measurement.

As for the PTC thermistors, their resistance increases with an increase in temperature. This makes them useful for overcurrent protection and self-regulating heating.

成本

The cost can vary from one thermistor to another. It comes down to where you want to use it. Looking at the various performance features of the thermistor can help you see if it is worth investing in one or not. So, make sure to balance between the price and functionality to get value for money.

How To Check a Thermistor

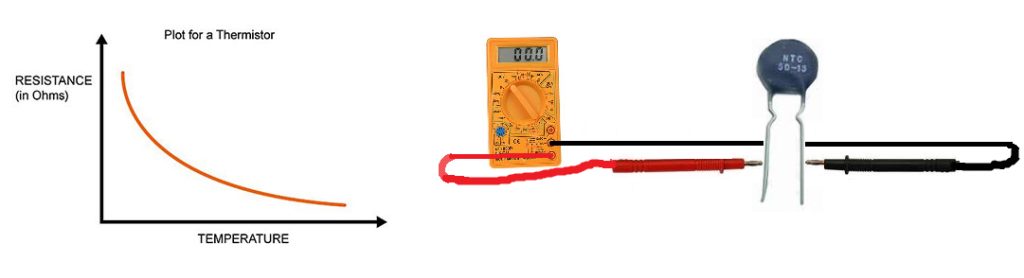

Thermistor sensors can be checked by using a multimeter. Let us say you are unsure if there is an issue with the thermistor; the multimeter will help you determine if it is still good or not.

Below is the process you can use to check the thermistor:

- Identify the type of thermistor you have. It can either be PTC or NTC.

- Gather the materials you will need, including a multimeter, a heat source, and a container with ice water.

- Set up the multimeter in resistance or ohms mode.

- Measure the resistance of the thermistor at room temperature and record it. We will use it to compare with the other values later.

- Apply heat gradually to the thermistor by using a heat source. Something like hot water or a hair dryer will do. Observe how the resistance reading changes. In the case of an NTC thermistor, the resistance decreases as it heats up. As for the PTC thermistor, the resistance will increase with the increase in temperature.

- Lower the temperature of the thermistor by applying cold water and observe the change as well. In this case, the NTC thermistor will have an increase in resistance with the reduction of temperature, while the PTC thermistor resistance will decrease with the decrease in temperature.

- Compare these values with what you have in the datasheet of the thermistor to see if they are still within the indicated range.

When you notice the resistance does not change as expected or remains constant, it means the thermistor might be faulty and needs replacement.

結論

Thermistors play a key role in helping you measure temperature changes in an application. It is for this reason that you will find it a good choice for various applications. There are two main types of thermistors: NTC and PTC thermistors. Each has applications due to its functionality. Always ensure that you assess your application needs and choose something that works well for you. Buying from top brands can assure you of the best performance features and reliability as well.

Video: Thermistor Basics – NTC PTC

請發送 RFQ,我們將立即回覆。

常見問題

Are thermistors better than RTDs or thermocouples?

It comes down to the application. Thermistors are more accurate and sensitive, mostly in limited temperature ranges. If you have to measure temperature in industrial applications or high-temperature environments, RTDs or thermocouples may do a better job.

Can thermistors be used with Raspberry Pi and Arduino?

Yes, thermistors can be connected to microcontrollers such as Arduino in various circuits for example, voltage dividers. You may need calibration data or look-up tables for the best performance and accurate readings.

Is it possible for thermistors to fail?

Yes. Thermistors can fail because of overheating, moisture intrusion, or mechanical damage. When designing circuits, it is essential to use protective coatings and ensure that power ratings are adhered to, thereby preventing such failures.